26

2024

Comprehensive Analysis and Selection of Flake Ice Machine

In the field of modern industry and food preservation, flake ice machine, as an important ice-making equipment, plays a vital role. Different types of flake ice machines, such as freshwater flake ice machine, seawater ship flake ice machine and seawater land flake ice machine, are favored because of their unique advantages and application scenarios. This article will introduce the working principle, main features and specific applications of these three flake ice machines in different fields in detail, to help you better understand and choose the ice-making equipment that best suits your needs. 1. Freshwater flake ice machine Freshwater flake ice machine is an ice-making equipment widely used in food preservation, industrial cooling and chemical processing. Its ice-making principle is to spray water on the surface of the cooling plate, quickly freeze the water into flake ice through the refrigerant in the cooling plate, and scrape the i […]

10

2024

Cube ice machine: structure, principle, types and applications

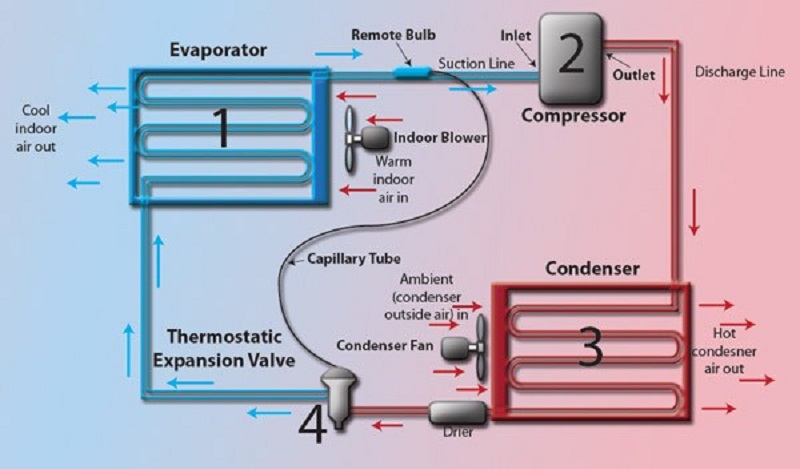

The particle ice machine is a device specially used to produce particle ice cubes. Its basic structure mainly includes the following parts: Compressor: It is the core component of the particle ice machine and is responsible for compressing the refrigerant to produce a freezing effect. Evaporator: It converts water into ice by absorbing heat and is the main component of the ice machine to freeze water. Condenser: Cools the compressed refrigerant, usually by air cooling or water cooling. Ice storage bucket: It is used to store the produced particle ice and usually has a heat preservation function to maintain the quality of ice cubes. Control system: It includes electrical control and programming systems to monitor and adjust the entire ice making process. The working principle of the particle ice machine is based on the refrigeration cycle and the water freezing process. First, the compressor compresses the low-pressure refrigerant into a […]

3

2024

Make You Know More About Direct Cooling Block Ice Machine!

Block ice machine is a common ice-making equipment, widely used in food preservation, cold chain transportation, industrial cooling and other fields. Block ice machine is mainly divided into two types: direct cooling block ice machine and brine block ice machine. This article will focus on the direct cooling block ice machine, and explore its working principle, advantages and disadvantages, and application in different fields. Direct cooling block ice machine makes ice by direct contact with refrigerant. This design eliminates the intermediate medium, making the heat exchange process more efficient. The working principle of direct cooling block ice machine is as follows: The refrigerant directly contacts the ice-making mold through the cooling pipe. Water is poured into the mold and freezes quickly under the action of the refrigerant. When the ice reaches the predetermined thickness, the refrigerant stops circulating, the mold is heated […]

26

2024

The History and Future of Cold Storage

The development of cold storage can be traced back to the time when humans began to use natural ice and snow to preserve food. With the advancement of science and technology, cold storage technology has gradually evolved and has gone through several important stages. In ancient times, humans relied on natural ice and snow to preserve food. For example, ancient Chinese ice cellars used ice and snow collected in winter to store food, and ancient civilizations such as Egypt, Greece, and Rome also had similar technologies. Although this method is simple, it is limited by climatic conditions and storage time. In the early 19th century, mechanical refrigeration technology began to appear, marking a revolutionary advancement in cold storage technology. In 1805, American Oliver Evans designed the first vapor compression refrigerator. Subsequently, John Gorrie of Britain and Carl von Linde of Germany successfully manufactured practical refrigera […]

19

2024

Refrigeration System Maintenance and Troubleshooting Guide

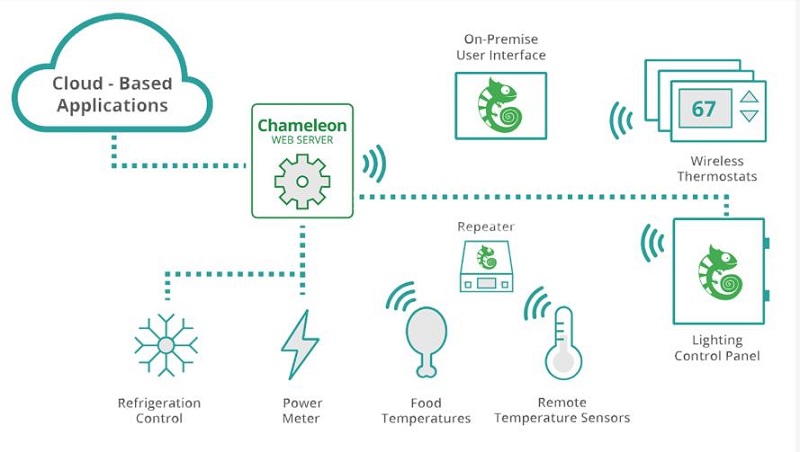

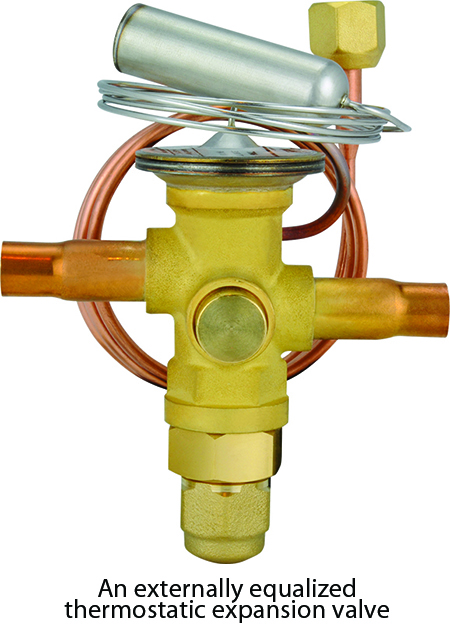

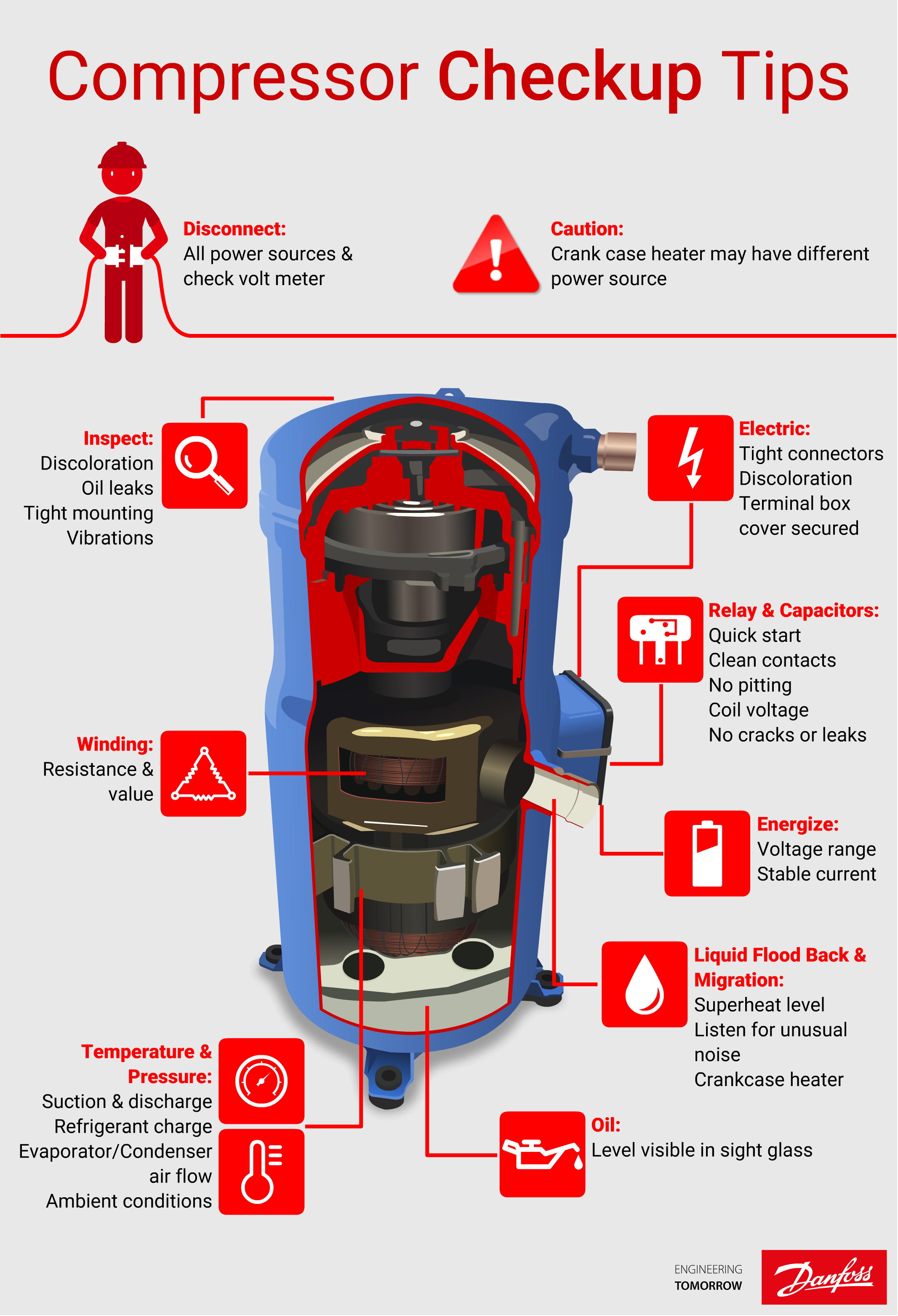

The refrigeration system is a general term for the equipment and pipelines through which the refrigerant flows, including compressors, condensers, throttling devices, evaporators, pipelines and auxiliary equipment. It is the main component system of air conditioning equipment, cooling and refrigeration equipment. The blockage failure of the refrigeration system has many forms such as ice blockage, dirty blockage and oil blockage. The unified fault characteristics of blockage are: the condenser is not hot when touched, the evaporator is not cold, the compressor operating current is smaller than normal, the pressure gauge is connected to the bypass charging valve, indicating negative pressure, the outdoor unit is running light, and there is no sound of liquid in the evaporator. Causes and fault phenomena of ice blockage The occurrence of ice blockage failure is mainly due to excessive moisture in the refrigeration system. With the continu […]

14

2024

The Role of Flake Ice Machines in Food Preservation

In today’s ever-evolving food industry, where freshness and quality are paramount, the role of flake ice machines in food preservation cannot be overstated. These machines, with their remarkable ability to provide large contact areas and rapid cooling speeds, play a crucial role in preserving perishable goods, particularly seafood. Let’s delve deeper into the significance of flake ice machines and their impact on food preservation. Food preservation has been a fundamental aspect of human civilization, dating back to ancient times when techniques like drying, salting, and fermentation were employed to prolong the shelf life of perishable items. However, with advancements in technology, modern methods of food preservation have emerged, offering more efficient and effective ways to maintain food freshness and quality. Among these methods, the use of flake ice machines stands out as a game-changer in the food industry. Fl […]

7

2024

Focusun Tube Ice Machine: Innovating Ice Making Technology and Applications

As the beverage industry continues to evolve and consumer tastes shift, ice making technology is also constantly innovating and advancing. Among these innovations, the Focusun tube ice machine, as an emerging ice making equipment, is gradually attracting attention and application. This article will delve into the working principle, features, and applications of the Focusun tube ice machine in various fields, as well as its future development trends in the ice making technology sector. Working Principle of Focusun Tube Ice Machine The Focusun tube ice machine is a device that utilizes freezing technology to manufacture tube-shaped ice blocks. Its working principle mainly includes the following steps: Condensation Process: The tube ice machine is equipped with a condenser, which lowers the temperature inside the ice-making chamber to below freezing point through compression equipment such as a compressor, causing water inside the pipes to […]

28

2024

Types of Commercial Ice Machines

In modern business and catering, keeping food and drinks cold is key to ensuring product quality and customer satisfaction. As an important equipment in this process, commercial ice making machines meet the ice making requirements of different places and needs with their high efficiency, stability and diversification. This article will introduce in detail different types of commercial ice machines and their application scenarios, such as pellet ice machines, tube ice machines, ball ice machines, bullet ice machines and snowflake ice machines. The granular ice machine cools and condenses water into fine granular ice cubes through the refrigeration system. This kind of ice cube is suitable for beverage preparation, food preservation and other fields. The advantage of the granular ice machine is that it makes ice quickly, the ice cubes are uniform in size and easy to melt, and can quickly reduce the temperature of food and beverages. In co […]

22

2024

Multiple Applications of Block Ice

In modern industrial and agricultural fields, the application of block ice has become increasingly widespread. Large block ice is not only popular because of its large size and good cooling effect, but also because of its easy storage and transportation, it has become an indispensable part of many industries. Below, we will delve into the application of block ice in areas such as fishing boat processing and livestock cooling. In the fishing industry, block ice is vital to maintaining the freshness and quality of seafood. When large fishing boats go out to sea to catch fish, they often carry large amounts of ice to freeze captured fish, shrimp and other seafood in a timely manner. The rapid cooling effect of block ice can effectively prevent seafood from spoiling, extend its shelf life, and ensure that consumers can taste fresh and delicious seafood products. In addition, block ice also plays an important role in the processing workshops […]

16

2024

Slurry Ice Machine: The New Star of Refrigeration Technology

With the continuous advancement of science and technology, refrigeration technology is also constantly developing. Among many refrigeration technologies, liquid ice machines have gradually emerged with their unique advantages and become a new star in the future refrigeration field. This article will introduce in detail the working principle, characteristics, application fields and future development prospects of the fluid ice machine. The liquid ice machine is a refrigeration equipment that uses special technology to quickly convert liquid water into liquid ice. Its working principle mainly includes the following steps: Water circulation: The liquid ice machine sends liquid water into the refrigeration system through a water pump to form a cycle. Rapid refrigeration: In the refrigeration system, the liquid water undergoes a rapid refrigeration process and the temperature drops rapidly. Formation of fluid ice: As the temperature decrease […]

11

2024

Snow Flake Machine: The Essential Tool for Cooling Summer Days

In the scorching summer, chilled beverages become the top choice for seeking refreshment. At this time, the snow flake machine becomes the weapon of choice for many businesses and households. Not only can it produce finely textured, refreshing snow flake ice, but it also adds beauty and texture to beverages. The snow flake machine is a device that produces extremely thin ice flakes by turning water or juice into a slushy mixture similar to snowflakes. Its working principle involves high-speed rotating blades that shave ice cubes or ice block mixtures into extremely fine ice flakes, resulting in a light and soft texture. Snow flake machines have wide-ranging applications in both commercial and household settings. In commercial establishments such as coffee shops, beverage shops, dessert parlors, etc., snow flake machines are often used to make various snow-capped drinks, slushies, chilled beverages, etc., providing customers with cool en […]

7

2024

High-efficiency Chiller Creates A Cool Workshop Environment

As summer approaches, high temperatures and intense heat have become a major challenge for many workshops and companies. In such an environment, how to create a comfortable and cool working environment for employees and improve work efficiency has become an issue that every business manager must consider. At this time, high-efficiency chillers become the ideal choice to solve this problem. As a professional refrigeration equipment, the working principle of the chiller is to transport cold water to the place that needs to be cooled through the circulation refrigeration system. Through the heat exchange between water and air, the heat in the workshop is taken away to achieve the cooling effect. . Compared with traditional fans and air conditioners, chillers have higher cooling efficiency and lower energy consumption, and are especially suitable for large-area, high-load cooling needs such as workshops. There are many advantages to using a […]

29

2024

Vacuum Pre-cooling Machine: A Powerful Tool For Efficient Cooling

With the continuous advancement of science and technology, various efficient and energy-saving cooling equipment have gradually entered people’s field of vision. Among them, the vacuum precooling machine, with its unique vacuum precooling technology, has shown wide application prospects in agricultural products, food processing and other fields. This article will introduce in detail the working principle, application industry, advantages and disadvantages and future development of vacuum precooling machine, in order to provide readers with a comprehensive and in-depth understanding. 1. Working principle of vacuum precooling machine The vacuum precooling machine uses vacuum precooling technology to reduce the air pressure by extracting air and water vapor from the vacuum tank, thereby achieving rapid cooling of objects. In a low pressure environment, the boiling point of water decreases and the latent heat of evaporation increases, […]

25

2024

Tube Ice Machine – Innovative Technology Leads The Cold Chain Industry

In the modern cold chain industry, tube ice machines are undoubtedly a key technology, providing reliable solutions to the refrigeration needs in the fields of food, medicine, and chemicals. As an efficient and energy-saving refrigeration equipment, the tube ice machine makes a positive contribution to the environmental load while maintaining product freshness and quality. This article will deeply explore the working principle, application fields and future development trends of tube ice machines. The tube ice machine is a device that uses cooling medium to circulate in the pipeline. Its basic working principle is similar to traditional refrigeration systems, but with higher efficiency and lower energy consumption. The low-temperature refrigerant is compressed into high-temperature and high-pressure gas through the compressor, and then cooled into a liquid through the condenser, and then cooled and decompressed through the expansion val […]

19

2024

Plate Ice Machine: Innovation and Application of Refrigeration Technology

在现代冷链行业中,管冰机无疑是一项关键技术,为食品、医药和化工等领域的冷藏需求提供了可靠的解决方案。管冰机作为一种高效、节能的冷冻设备,在保持产品新鲜度和质量的同时,也对环境负荷做出了积极的贡献。本文将深入探讨管冰机的工作原理、应用领域以及未来发展趋势。 管冰机是一种利用冷却介质在管道内循环流动的设备。其基本工作原理类似于传统的制冷系统,但具有更高的效率和更低的能耗。通过压缩机将低温制冷剂压缩成高温高压气体,然后通过冷凝器使其冷却成液体,再通过膨胀阀降温和降压,最终进入蒸发器,在管道内循环流动,吸收热量并使管道表面结冰,从而实现冷藏效果。 管冰机在各个领域都有广泛的应用,主要包括以下几个方面: 食品冷藏:管冰机广泛应用于食品加工和存储行业,如冷冻肉类、水产品、果蔬等。其稳定的温度控制和高效的冷却能力,保证了食品的新鲜度和品质。 医药保鲜:在医药行业,管冰机被用于冷藏药品和生物制品,确保其在整个供应链中的稳定温度和质量。 化工工业:在化工领域,管冰机常用于冷却反应器和保持化学物质的稳定性。 超市冷藏展示:管冰机还被广泛应用于超市和商场的冷藏展示柜中,展示各种冷冻食品和冷饮。 随着科技的不断进步和环保意识的增强,管冰机在未来将呈现出以下几个发展趋势: 节能减排:未来的管冰机将更加注重节能减排,采用更环保的冷媒和高效的制冷技术,降低能耗和碳排放。 智能化管理:随着物联网和人工智能技术的发展,管冰机将实现远程监控和智能化管理,提高运行效率和故障预警能力。 多功能集成:未来的管冰机可能会与其他设备集成,实现多功能化,如冷热联合供应、热回收利用等,提高资源利用效率。 生物冷冻技术:随着生物技术的发展,管冰机将在生物冷冻领域发挥更重要的作用,为生物样本的冷藏和运输提供更可靠的解决方案。 综上所述,管冰机作为冷链行业的重要技术装备,不断推动着行业的发展和进步。未来随着科技的不断创新和应用场景的扩大,管冰机将继续发挥着重要的作用,为社会经济发展和人类生活提供更加可靠、高效的冷藏解决方案。

10

2024

Ice Sheet Machine: Excellent Refrigeration Efficiency and Widespread Application

In modern society, refrigeration equipment has become an indispensable part of various industries. Among them, the ice flake machine, as an efficient and convenient refrigeration device, is highly regarded in many industries due to its exceptional cooling effect and widespread application areas. Especially in the field of seafood processing, the ice flake machine plays an irreplaceable role. Firstly, the ice flake machine is renowned for its outstanding cooling effect. Compared to traditional ice cubes, the ice flakes produced by the machine have a larger surface area, enabling them to absorb and dissipate heat more quickly. This means that within the same period of time, the ice flake machine can effectively lower the ambient temperature, providing a more suitable preservation environment for seafood. Additionally, the ice flake machine’s cooling effect is uniform and long-lasting, maintaining a low temperature for extended perio […]

28

2024

Highly Efficient Direct Cooling Block Ice Machine

In modern life, refrigeration technology is increasingly becoming an indispensable part of people’s lives. As a high-efficiency refrigeration equipment, the direct cooling block ice machine can not only meet people’s cooling needs, but also has the advantages of energy saving and environmental protection. The following editor will discuss in depth the characteristics of the direct cooling block ice machine and its importance in daily life from the aspects of working principle, structural design and application scenarios. Direct cooling block ice machine is a device that adopts the principle of mechanical compression cycle refrigeration. It mainly consists of four main components: compressor, condenser, expansion valve and evaporator. When the block ice machine starts running, the compressor will suck in low-temperature and low-pressure steam, and then increase its temperature and pressure through compression. Then, the high- […]

19

2024

Ice Machine With Great Potential – Slurry Ice Machine

With the rapid advancements in refrigeration technology, slurry ice machines are gradually emerging as a new benchmark in the refrigeration industry due to their exceptional cooling effects and wide range of applications. This innovative ice-making machine not only exhibits superior cooling performance but is also suitable for various settings such as seafood preservation, food processing, medical refrigeration, and many other industries, providing efficient and reliable refrigeration solutions. Utilizing advanced refrigeration technology, slurry ice machines precisely control the refrigeration process to rapidly transform liquid water into tiny ice crystal particles, creating slurry ice. This unique ice form offers remarkable cooling effects and fluidity. Compared to traditional ice cubes, slurry ice can penetrate the interior of cooled objects more quickly, achieving rapid and uniform temperature reduction. Additionally, its delicate […]

13

2024

Direct Cooling Block Ice Machine

Direct cooling block ice machine, as a shining pearl in modern refrigeration technology, plays an irreplaceable role in many fields with its efficient, stable and reliable performance. This article will provide an in-depth explanation of the working principle of the direct cooling block ice machine and explore its wide range of application scenarios. The direct cooling block ice machine adopts a direct cooling refrigeration system, which uses the refrigerant to absorb heat in the evaporator to achieve a cooling effect. Its working principle is relatively simple but efficient, and mainly includes the steps of refrigerant circulation, evaporator cooling, ice forming and demoulding. The refrigerant circulates under the action of the compressor and absorbs heat from the environment when passing through the evaporator, causing the surface temperature of the evaporator to decrease. At the same time, the water source is evenly distributed on t […]

8

2024

Vacuum precoolers: revolutionary equipment for the agricultural and food processing industries

In today’s fast-paced life, food preservation is a topic of great concern. As an important technology in the field of food preservation, vacuum precooling machine is widely used in the processing of fruits, vegetables, flowers and cooked foods. This article will delve into the application and significance of vacuum precoolers. Vacuum precooling machine is a device that uses a vacuum environment for cooling processing. The principle is to place the food or other items being processed in a vacuum state and use reduced pressure to quickly evaporate the water on the surface to achieve rapid cooling. Vacuum precooling machines can be divided into fruit, vegetable and flower vacuum precooling machines and cooked food vacuum precooling machines according to different needs. Vacuum pre-cooling machine for fruits, vegetables and flowers. In the fruit, vegetable and flower industry, maintaining the freshness and quality of products is cruci […]

29

2024

Focusun flake ice machine and cold storage integrated machine

In today’s rapidly developing food, pharmaceutical and logistics industries, there is an increasingly urgent need for efficient and convenient refrigeration solutions. In order to meet this demand, we have launched a combination of flake ice machine and cold storage all-in-one machine, providing users with a new refrigeration experience. The flake ice machine, as one of the core equipment of this combination, is highly praised for its efficient production capacity and excellent flake ice quality. Using advanced refrigeration technology, it can quickly and continuously produce large quantities of high-quality flake ice. At the same time, the intelligent control system of the flake ice machine ensures the stability and reliability of production, providing users with a steady supply of flake ice. The integrated cold storage machine that works closely with the flake ice machine stands out for its powerful storage capacity and efficien […]

23

2024

Cube Ice machine: A Powerful Assistant in Many Fields

In many fields such as catering, medical care, scientific research, etc., cube ice machines have become an indispensable equipment. With its efficient and convenient ice making method, this equipment provides a stable and reliable ice source for many industries, assisting the daily operations and development of various industries. 1. Structure and working principle of pellet ice machine Pellet ice machine is mainly composed of compressor, condenser, evaporator, ice mold and other parts. When the machine starts, the compressor starts to work, compressing the refrigerant into high-temperature and high-pressure gas, which then enters the condenser for cooling. The cooled refrigerant enters the evaporator, absorbs heat and produces a cooling effect. At this time, the water molecules in the ice mold condense into ice, eventually forming ice cubes. 2. Application fields of cube ice machine Catering industry: In the catering field, cube ice ma […]

19

2024

Slurry Ice Machine: Injecting New Vitality Into Cold Chain Logistics

Slurry ice is made up of millions of ice “microcrystals.” Compared to other types of ice, ice particles are smaller in size and have a larger heat transfer area, so they cool faster. It is commonly used in a variety of industries such as the cooling and storage of fish, produce, poultry and other perishable products. The principle of the slurry ice machine is to quickly cool and convert liquid water into tiny ice crystals through a specific refrigeration system and process, and mix them with a small amount of aqueous solution to form the unique form of liquid ice. Here are the detailed steps on how a slurry ice machine works: Refrigerant cycle: The compressor in the refrigeration system sucks in low-temperature and low-pressure refrigerant gas and compresses it into high-temperature and high-pressure gas. Condenser cooling: The high-temperature and high-pressure refrigerant gas enters the condenser, and through contact with […]

2

2024

Flake Ice Machine: Innovation in Food Preservation and Fishing Boat Processing Industry

In the modern food industry, the introduction of flake ice not only provides innovative solutions for food preservation, but also plays a key role in the fishing boat processing industry. This dual mission has brought revolutionary changes to the food industry, improving product quality, extending the shelf life of goods, and promoting the sustainable development of the entire industry. Flake ice plays a key role in food preservation. Its rapid cooling and even heat dissipation properties make it ideal for the food cold chain. Whether it is fresh produce, meat or cooked food, flake ice can effectively lower the temperature and delay the metabolic process of food, thus extending the shelf life of food. This is crucial to reducing food waste and improving food quality. In the fishing boat processing industry, flake ice provides an ideal solution for rapid cooling and preservation of seafood products. After fishing, the flake ice machine c […]

29

2024

How to Extend The Service Life of Cold Storage?

With the advancement of science and technology, cold storage is increasingly used in food, medicine, chemical industry and other fields. However, many people may not know how to use cold storage to extend its service life. Today, the editor will introduce to you in detail how to extend the service life of cold storage. 1. Choose high-quality cold storage equipment. The quality of cold storage equipment directly affects the service life of the cold storage. Therefore, when choosing cold storage equipment, you should pay attention to the quality and performance of the equipment, and choose regular brands and quality-assured equipment. At the same time, during the installation process, ensure that the equipment is installed in accordance with specifications to avoid equipment damage or affecting the service life of the cold storage due to improper installation. 2. Regular maintenance. Regular maintenance of cold storage equipment is the ke […]

24

2024

Concrete Cooling System Introduction

The concrete cooling system is a system designed to control concrete temperature, which plays an important role in construction and infrastructure projects. The temperature will increase during the process of hardening, which may lead to a series of problems, such as the formation of cracks and the reduction of concrete strength. To solve these problems, the concrete cooling system is widely used to ensure the quality and durability of concrete. The concrete cooling system is composed of cold water systems, shell ice system, automatic ice storage system, ice delivery system and weighing system. Next, the editor will introduce each system. Water chiller system: Water chillers can provide cold water and ice water with constant temperature, constant current, constant pressure. No matter how low the temperature of the water is, how large the cooling temperature difference is, and the level 1-4 cooling method can provide a complete set of co […]

22

2024

Introduction of Different Condensers

A condenser is a device used to cool and condense gas or vapor, converting it into a liquid state. In refrigeration equipment such as ice machines, refrigeration equipment, and air conditioning systems, the condenser is an important component. Its basic principle is to cool gas or vapor to a liquid state by dissipating heat. There are three common condensers: air-cooled condenser, water-cooled condenser and evaporative condenser. These three types of condensers have obvious differences in working principles and performance. Air-cooled condenser is a refrigeration method that dissipates heat through air circulation. This type of condenser usually uses a built-in fan to draw air into the condenser to dissipate heat. The advantage of air-cooled condensers is that they are easy to install and require no additional water source. However, it may be less effective in high temperature environments as it relies on the cooling effect of the air. […]

9

2024

The Difference Between Condensers

A condenser is a device used to cool and condense gas or vapor, converting it into a liquid state. In refrigeration equipment such as ice machines, refrigeration equipment, and air conditioning systems, the condenser is an important component. Its basic principle is to cool gas or vapor to a liquid state by dissipating heat. There are three common condensers: air-cooled condenser, water-cooled condenser and evaporative condenser. These three types of condensers have obvious differences in working principles and performance. Air-cooled condenser is a refrigeration method that dissipates heat through air circulation. This type of condenser usually uses a built-in fan to draw air into the condenser to dissipate heat. The advantage of air-cooled condensers is that they are easy to install and require no additional water source. However, it may be less effective in high temperature environments as it relies on the cooling effect of the air. […]

3

2024

The Convenience and Benefits of Direct Cooling Block Ice Machines

With the continuous development of industrial and commercial fields, direct cooling block ice machines, as an advanced and efficient refrigeration equipment, have brought significant convenience and benefits to all walks of life. Different from household refrigeration equipment, direct-cooled block ice machines have higher production capacity and wider application range. Here are several major advantages it brings. Efficient cooling capacity: Direct cooling block ice machines are known for their powerful cooling capabilities. It uses advanced refrigeration technology to quickly cool water in a short time and form solid, transparent block ice. This makes it perform well under large-scale refrigeration needs and meets the high requirements for rapid refrigeration in industrial and commercial fields. High quality ice: Ice cubes produced by direct-cooled block ice machines generally have higher purity and longer shelf life. Since no additiv […]

26

2023

Snowflake Ice Machine

With the arrival of summer, cool drinks have become an indispensable part of people’s lives. At this time, a modern snowflake ice maker became one of the popular kitchen appliances. This article will provide an in-depth introduction to the working principle, characteristics, and widespread applications of snowflake ice machines in daily life. A snowflake ice maker is a device that rapidly cools water molecules into snowflakes through an efficient refrigeration system. Its working principle mainly includes a refrigeration system, an ice scraping device, and an ice storage compartment. The refrigeration system circulates refrigerant, allowing water to quickly crystallize into snowflakes under the action of the ice scraping device, and then store it in a freezer for people to enjoy at any time. Advantages and characteristics: Quick ice making: The snowflake ice maker adopts advanced refrigeration technology, which can quickly cool wa […]

21

2023

Some Knowledge About Ice Flake Machines

Ice flake machine is a widely used equipment in food processing, beverage production, laboratories, hospitals, and other fields, with its main function of producing flake ice. Sliced ice has the advantages of fast production speed, good cooling effect, and convenient hygiene, so it is widely used in various occasions that require cooling and freezing. The structure and working principle of the ice maker are relatively simple. It mainly consists of refrigeration system, ice making system, ice sheet output system, etc. The refrigeration system is the core part of the ice maker, which reduces the temperature of ice sheets through refrigerant circulation. The ice making system consists of a set of ice blades and a refrigeration plate. When the ice blades rotate, they cool the liquid on the refrigeration plate into flakes of ice. The ice sheet output system is responsible for outputting the prepared ice sheets to the designated location. The […]

13

2023

Slurry Ice Machine: An Efficient Ice-making Solution

The slurry ice machine is an efficient, energy-saving and environmentally friendly ice-making equipment, which is widely used in food, chemical industry, medicine, aquatic products and other fields. This article will introduce in detail the characteristics, working principle, application fields and purchase suggestions of the slurry ice machine. The working principle of the slurry ice machine is mainly to absorb heat in the evaporator through the refrigerant, causing water to freeze into ice. When the refrigerant evaporates, heat is absorbed and the water is cooled into ice. The ice cubes are transported to designated locations via conveyor belts or pipes. At the same time, the slurry ice machine also has an automatic defrosting function, which can regularly clean the frost layer in the evaporator to ensure ice making efficiency. Characteristics of slurry ice machine Efficient ice making: The slurry ice machine adopts adva […]

5

2023

The Most Complete Introduction to Water Chillers, Come and Collect It!

The chiller is a refrigeration device widely used in industrial, commercial, and residential settings, primarily functioning to lower temperatures through refrigerant cycles. With features like high efficiency, energy saving, and environmental friendliness, chillers have found applications in various domains. This article provides a comprehensive overview of chillers, covering their principles, structure, characteristics, and applications. Working Principle of Chillers The working principle of chillers is based on the refrigerant cycle, consisting of four key steps: compression, condensation, expansion, and evaporation. Details are as follows: Compression: The refrigerant is compressed into a high-pressure gas in the compressor, with a concurrent rise in temperature. Condensation: The high-pressure gas undergoes heat exchange with the surrounding air or water in the condenser, gradually condensing into a high-pressure liquid. Expansion: […]

29

2023

Usage and Maintenance Strategy of Cold Storage in Different Seasons

As the seasons change, the usage and maintenance needs of cold storage also change accordingly. The temperature difference and humidity difference between winter and summer pose different challenges to the operation and maintenance of cold storage. In order to ensure the efficient operation of the cold storage and extend its service life, we need to take corresponding usage and maintenance measures based on the characteristics of these two seasons. Winter use and maintenance Energy saving control: In winter, the ambient temperature is low, and the energy consumption of cold storage is relatively low. However, it is still necessary to set the temperature reasonably to avoid excessive temperature fluctuations and maintain the quality of the items inside the cold storage. Insulation: Ensure that the cold storage door is well sealed to prevent the leakage of cold air. Regularly inspect the warehouse doors, door frames, and sealing strips, a […]

22

2023

Focusun Refrigeration deciphers cooling measures for concrete mixing plants

In the hot summer, the continuous rise in temperature will bring huge challenges to summer construction. According to the “Notice on Strengthening Concrete Construction and Maintenance Work in Summer”, mandatory measures must be taken to control the temperature of concrete and the characteristics of the mixture in concrete mixing stations. Especially for temperature control, temperature detection and recording should be done well. During summer concrete construction, the exit temperature of concrete should not be higher than 35°C, and the temperature of concrete entering the mold should not be higher than 30°C. 86-year-old German Focusun Refrigeration Since its establishment in 1929, Germany’s Focusun Refrigeration Focusun has always been committed to providing leading technologies and services in the refrigeration industry and delivering the most appropriate solutions to customers. So far, Focusun Refrigeration has ma […]

14

2023

How Much Do You Know About Water Chiller?

Water chiller is a refrigeration device that provides constant temperature, constant flow, and constant pressure cooling water. It absorbs indoor heat by circulating the refrigerant in the refrigeration system and releases the heat outdoors through the coolant. The working principle of water chiller is based on a refrigeration cycle, usually consisting of four main components, including a compressor, condenser, expansion valve, and evaporator. The following is a brief description of the working principle of the chiller: Compressor: The compressor is the core component of water chiller, responsible for compressing the refrigerant into high-temperature and high-pressure gas, and delivering it to the condenser. Condenser: The condenser is the second component of the refrigeration cycle, which converts high-temperature and high-pressure refrigerant into high-pressure liquid through cooling. The cooling method is usually achieved by dissipat […]

7

2023

Why suggest you choose a big brand for ice machine?

As an essential kitchen appliance in modern homes, commercial places and industrial fields, ice makers provide us with a convenient ice making solution. However, when purchasing an ice machine, some consumers may consider choosing cheaper, smaller brand products to save money. However, choosing an ice maker from a big brand is a wiser decision in the long run. In this article, we will explain why we should choose an ice machine from a big brand in terms of its working principle, quality assurance and after-sales service. Technology and performance Big brand ice machines often invest a lot of money in research and development, and have advanced technology and processes to ensure stable and reliable product performance. This means you can use your ice machine with confidence without having to worry about malfunctions or performance degradation at critical moments. On the contrary, ice machines of small brands may have some shortcom […]

31

2023

Cube ice machine——The best choice for commercial ice machines

Cube ice machine is a piece of equipment specially used to produce granular ice cubes. It has wide applications in many fields, such as food, beverage, medical and other industries. Next, the editor will introduce the concept, advantages and application scenarios of the cube ice machine in detail to help everyone better understand this practical equipment. The cube ice machine is an efficient and energy-saving ice-making equipment that uses advanced ice-making technology to quickly freeze water into ice cubes. This equipment comes in a variety of specifications and models to meet the needs of different occasions. Choosing a suitable cube ice machine mainly considers factors such as ice production capacity, ice cube size, and energy consumption. Advantages of cube ice machine Easy to use: The cube ice machine is easy to operate. You only need to connect to the water source and power supply to automatically make ice. The ice […]

24

2023

Ice Storage Facilities: A Crucial Tool in Refrigeration Technology

An ice storage facility is a facility specifically designed to store ice or refrigerant to provide refrigeration when needed. They are often An ice storage facility is a facility specifically designed to store ice or refrigerant to provide refrigeration when needed. They are often used in places that require large amounts of refrigeration, such as food processing plants, medical facilities, supermarkets, catering industries, etc. The following are some basic features and working principles of ice storage: Refrigeration principle: The basic principle of ice storage is to store cold energy in the ice storage by cooling the refrigerant (such as chilled water or specific chemicals) to extremely low temperatures. When cooling is required, the ice storage releases the stored cold energy to lower the temperature of the surrounding environment. Features: Refrigeration energy storage: The main function of the ice storage is to cool the refrigera […]

17

2023

Cold Storage Development Trends and Applications in Future

As an important link in refrigerated logistics, cold storage has been widely used in food, medicine, chemical industry and other fields. With the continuous advancement of science and technology, cold storage management is facing many challenges and opportunities, and its development directions are becoming increasingly diversified. This article will start from the current status and problems of cold storage management, analyze the development trends and practical applications of cold storage in the future, in order to provide useful reference for related industries. Current status and problems of cold storage management At present, cold storage management mainly has the following problems: High energy consumption: The operation of cold storage requires a large amount of energy, such as electricity, gas, etc., especially when the refrigeration equipment is operated for a long time, the energy consumption is more serious. High operating […]

10

2023

Is the ice produced by machine the same as naturally formed ice?

As is well known, ice can be formed in two ways, one through an ice maker, and the other under natural conditions. So, is the ice produced by the ice making mechanism the same as naturally formed ice? This article will analyze and compare from multiple perspectives. 1、 The difference between ice making mechanism ice and naturally formed ice An ice maker is a mechanical device that cools water below the freezing point through a refrigeration system, fixing water molecules together to form ice cubes. Compared to ice formed under natural conditions, ice produced by the ice making mechanism is more rapid, convenient, and controllable. Natural ice is formed by condensation of water vapor on the surface of an object under cold environmental conditions. It requires a certain amount of time and specific meteorological conditions to form, so it is relatively slow and unpredictable. Naturally formed ice typically has irregular shapes, and its tex […]

27

2023

Vacuum Cooling Machine: An Efficient and Energy-saving Cooling Solution

As a critical cryogenic equipment in food, medicine, electronics and other fields, vacuum cooling machines have become an indispensable part of various cooling processes. The vacuum cooling machine provides an efficient and energy-saving cooling solution through its unique cooling method. This article will detail the working principle, characteristics, and application areas of the vacuum cooling machine, aiming to provide reference for readers in related fields. Working Principle The vacuum cooling machine mainly utilizes the principle of rapid evaporation under vacuum conditions to cool objects. Specifically, the vacuum cooling machine consists of a vacuum pump, a refrigeration system, and a sealed container. In the sealed container, the refrigeration system cools the object to a set temperature through a refrigerant, and then the vacuum pump starts to work, removing the air inside the container and creating a low pressure envir […]

21

2023

What does a concrete cooling system consist of? How it works

A concrete cooling system is composed of the following components and operates as follows: Water Source or Cooling Medium: The cooling system requires a cooling medium to reduce the temperature of the concrete. This can be cold water, a coolant, or another cooling medium. Water Pump: The water pump is used to transport the cooling medium from the water source to the concrete structure. These can be centrifugal pumps or other types of pumps, depending on the system’s design and requirements. Distribution System: This system is used to distribute the cooling medium within the concrete structure, typically achieved through a network of pipelines. Spray Nozzles or Pipes: Spray nozzles or pipes are responsible for evenly spraying or injecting the cooling medium onto the surface or inside of the concrete. This effectively absorbs heat, thereby reducing the concrete’s temperature. Temperature Monitoring System: This system typicall […]

13

2023

Is There Really A Fully Automatic Ice Machine?

In the era of modern industrialization, ice machines have become indispensable equipment in catering, medicine, logistics and other industries. With the continuous development of technology, the functions of ice machines have also been continuously upgraded, and one of the most prominent features is fully automated operation. Our company’s ice making machine is one of the representative products. It realizes one-touch ice making, ice removal and ice pushing, which provides users with great convenience and also improves the production efficiency and use of ice cubes. Convenience. The Focusun ice machine is an advanced ice-making equipment that adopts the latest ice-making technology and combines it with an intelligent control system to enable a fully automated ice-making process. It has efficient ice-making performance while ensuring the hygiene and safety of the ice-making process, and is suitable for many different occasio […]

6

2023

Can the ice machine used for a long time?

Ice makers can usually operate continuously for a certain period of time, but it is not recommended to operate continuously for a long time. After each ice making process is completed, it usually requires a waiting time for the machine to cool down to ensure normal operation. The waiting time for the machine to shut down varies depending on the production capacity and model. Please consult the manufacturer for specific information. In addition, the working environment of the ice maker and the quality of the machine itself can also affect its performance and lifespan. The following are possible problems that may occur when the ice maker is used continuously for a long time, as well as precautions during use. Generally speaking, ice makers need to stop and wait for a period of time after each ice making process. If used continuously, the following problems may occur: 1. Overheating problem: Long term continuous operation can cause the ice […]

28

2023

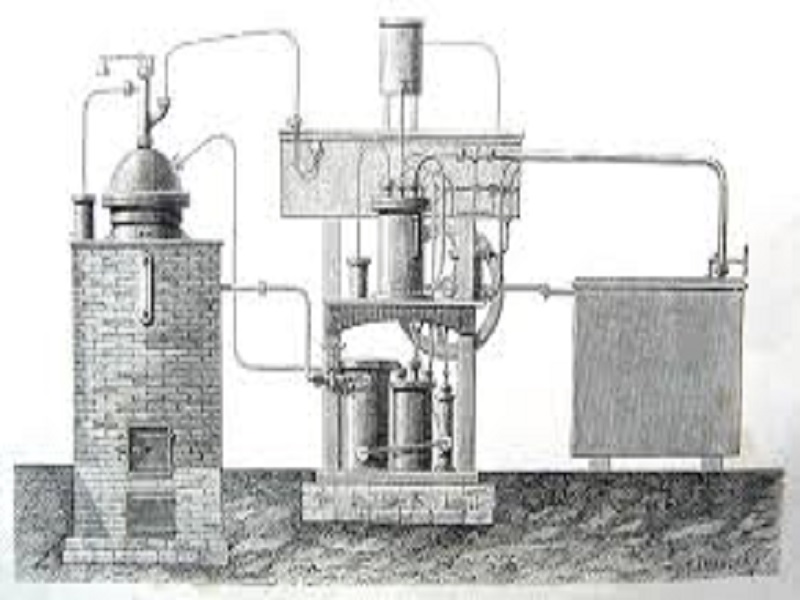

From Evaporative Cooling to Diversification: The Evolution of the Ice Machine

The history of ice-making machines dates back to the 19th century, evolving from initial experimental stages to becoming commercial and household appliances as technology advanced. Here are some key stages in the history of ice-making machines: John Gorrie’s Ice Machine (1854): American inventor John Gorrie created the world’s first commercial ice-making machine, which utilized the principle of evaporative cooling to produce ice blocks. This invention drove the commercial production of ice and transformed food storage and transportation methods. Ammonia Refrigeration by Ferdinand Carré (1876): French engineer Ferdinand Carré invented the first refrigeration machine that used ammonia as a cooling agent, marking a significant breakthrough in cooling technology. The application of ammonia refrigeration contributed to further developments in ice-making machines. Carl von Linde’s Ice Machine (1880s): German engineer […]

21

2023

The Gospel of Cooked Food Stores – Vacuum Pre Cooler

Many people who want to operate restaurants and food factories don’t know how to improve the shelf life of food. Most of them cool the food by air cooling, water cooling, ice cooling, etc., and then put it in the freezer and cold storage. Today, I would like to recommend a device for you, which can cool cooked food at 90°C to normal temperature 25°C in about 25 minutes, and below 10°C in 30 minutes. It can quickly pass through the high-speed breeding area of bacteria (30°C~60°C), control the increase of bacteria, and improve the hygiene and safety of food. This equipment is the cooked food vacuum pre-cooler, which is an indispensable food machinery equipment in developed countries such as Europe and the United States to solve the problem of high-temperature cooked food fresh-keeping packaging. Main function: remove the heat left by cooking food. Solving the problems of excessive bacteria, long time, and high energy consumption in […]

15

2023

Can the ice machine be used continuously for a long time?

Ice machines can usually run continuously for a limited amount of time, but running them uninterrupted for long periods of time is not recommended. After each ice making is completed, it usually takes a waiting time for the ice machine to cool down, so as to ensure the normal operation in the future. The waiting time for the ice machine with different output and model is also different, please consult the manufacturer for details. . In addition, the working environment of the ice machine and the quality of the machine itself will also affect its performance and life. The following are the problems that may occur when the ice machine is used continuously for a long time, and the precautions during use. Generally speaking, the ice machine needs to be shut down and wait for a period of time after each ice making is finished. If it is used continuously, the following problems may occur: 1. Overheating problem: Continuous operation for a lon […]

9

2023

Frequent problems with the ice machine? May be these reasons

During the use of the ice machine, various failures may occur. (The editor hereby reminds everyone that it is more reliable to choose some big brands for such large-scale mechanical equipment). If you have purchased an ice machine, but often cannot be turned on or there is a problem with the ice making process, you can refer to the following reasons to troubleshoot. 1. Poor manufacturing quality: Some ice makers may have flaws in the manufacturing process, which makes them prone to problems during use. This may involve aspects such as component design, material selection or manufacturing processes. 2. Improper use and maintenance: The ice machine needs to be used and maintained correctly in accordance with the instructions in the user manual. If the user uses or maintains the ice machine incorrectly, such as irregular cleaning, maintenance of parts, etc., it will easily lead to failure. 3. Environmental conditions: Ice machines usually […]

1

2023

The most complete cube ice machine explanation!

In the hot summer, cold drinks have become the best choice for people to cool off. In milk tea shops, coffee shops and other beverage shops, the cube ice machine has become an important equipment, bringing people cool and refreshing drinks. Next, I will give you an in-depth understanding of this refrigeration equipment from the structure, principle, characteristics and application of cube ice machine. First of all, cube ice machines are commercial ice machines. In addition to cube ice machines, other commercial ice machines include snowflake machines, shaving ice machines, bullet ice machines, lunar-shaped ice machines, spherical ice machines, and milk ice machines. Commercial cube ice machines are basically integrated, including compressors, condensing fans, microcomputer PC boards, etc. Next, let’s take a look at the principle of the cube ice machine. In order to facilitate everyone’s understanding, we divide […]

24

2023

How long will it take to buy an ice maker for milk tea business?

Purchasing an ice-making machine as part of a bubble tea business, the payback period depends on several factors. These factors include the price of the ice-making machine, the sales volume and profit margin of the bubble tea shop, the demand for ice products, and the operating costs. In this article, we will analyze these factors and discuss the payback period of purchasing the ice-making machine. 1, Ice-making machine price and model selection Firstly, one of the key factors in determining the payback period is the price of the ice-making machine. The price of ice-making machines varies depending on the brand, model, and production capacity. High-priced ice-making machines usually have higher production capacity and more advanced functions but may require a longer payback period. When purchasing an ice-making machine, it is recommended to choose a model that suits the scale and sales volume of the bubble tea shop. If the daily […]

18

2023

What is the concrete cooling system? What does it do

Concrete cooling system is a kind of equipment or technology used to control the temperature of concrete. During concrete construction, temperature control is very important because high temperatures may cause problems such as premature drying, cracking or loss of strength of the concrete. The main objective of a concrete cooling system is to ensure the ideal conditions for hardening and strength development during construction by controlling the temperature of the concrete. Here are some common concrete cooling systems: Cooling water system: This system uses cooling water to regulate the temperature of the concrete. Cooling water can be sprayed on the concrete surface through water pipes or spray system to absorb heat and reduce the temperature of concrete. Pre-cooling system: Before the concrete is put into use, use the pre-cooling system to cool down the raw materials. This can be achieved by cooling the aggregate, water or ad […]

10

2023

The most romantic snow machine – Focusun snow falling machine

Walking in the snowy season is an excellent enjoyment, but unfortunately the reincarnation of the four seasons is an unstoppable natural phenomenon, so in the past people could only wait until winter to get this kind of enjoyment, but now Focusun makes snow falling machine allow people to enjoy the romance that can only be obtained in winter at any time. Natural ingredients without any worries Focusun snow falling machine uses tap water as the main raw material, through compression refrigeration, supplemented by Focusun’s excellent snow flake clutch technology, to form artificial snow with a high degree of simulation. If the device is placed at an altitude of 3-5 meters, it can achieve the effect of natural snowflakes falling and flying all over the sky. This kind of artificial snow feels cold, looks like natural snow, and has the characteristics of light and flying snowflakes. Easily make snow without fear of any en […]

5

2023

Vacuum Precooler: Advanced Technology for Rapid Cooling and Preservation

Vacuum precooler is a kind of equipment used for rapid cooling and preservation of food. It lowers the temperature of food by reducing air pressure in a vacuum environment. The main principle of vacuum pre-cooling technology is to use the principle of evaporation and heat dissipation of water to achieve the effect of cooling by reducing the humidity and evaporation temperature of the food surface. Vacuum pre-coolers are mainly divided into fruit, vegetable and flower vacuum pre-coolers and cooked food vacuum pre-coolers, and they will be introduced below: Fruit, vegetable and flower vacuum precooler: The fruit, vegetable and flower vacuum precooler is mainly used for cooling and preservation of fresh agricultural products such as fruits, vegetables and flowers. It quickly reduces the temperature of produce, extending its shelf life and reducing spoilage and quality loss. The vacuum precooler for fruits, vegetables and flowers usu […]

26

2023

A good partner in fishery production——Flake ice machine

Flake ice machine is a kind of equipment specially used to make ice flakes. It uses refrigerant to quickly reduce the temperature of water and freeze it into ice sheets through a refrigeration cycle system. The flake ice machine has the characteristics of fast ice making, large-capacity storage, automatic control and various ice flake options. It is widely used in the catering industry for making iced drinks, juices, smoothies and refrigerated food. At the same time, it also plays an important role in household use, commercial places, medical institutions and refrigerated transportation. So, how much do you know about flake ice machines? First of all, flake ice machines can be divided into fresh water flake ice machines and sea water flake ice machines. The seawater flake ice machine is specially designed for marine ice-making operations to overcome seawater corrosion, pitching and swaying of ships and other characteristics. Among them, […]

14

2023

Focusun Snow Maker – Specifically Designed for High-temperature Areas

High temperature snow maker is a new type of snowflake manufacturing equipment that can produce real snowflakes in high-temperature environments. The high-temperature snowmaker produced by Ferguson can work in a high temperature environment of 35 degrees Celsius, providing not only the needs of winter ski resorts, but also ice and snow entertainment projects for summer resorts, theme parks, etc. At the same time, we also provide rental services for high-temperature snowmaking equipment, providing customers with more flexible and customized snowflake manufacturing solutions. High temperature snow maker structure Container ice maker: With a snow production capacity of up to 100 cubic meters per day, it can produce snow indoors and outdoors. The snow is dry and soft, suitable for various snow activities. Container type automatic rake type ice storage: Fully automatic rake type ice storage, with functions such as automatic storage, leveling […]

6

2023

How to choose cold storage? Let me tell you!

Choosing cold storage depends on your specific needs and requirements. Here are some factors to consider when selecting cold storage: Temperature Range: Determine the temperature range you require for your products. Cold storage facilities offer different temperature zones, such as refrigerated (2-8°C), chilled (8-15°C), or frozen (-18°C and below). Ensure that the storage provider can maintain the desired temperature consistently. Capacity: Assess the amount of storage space you need. Consider both the current and future storage requirements of your products. Choose a facility that can accommodate your inventory volume and offers scalability options if your needs expand. Location: Consider the proximity of the cold storage facility to your business operations or distribution network. A convenient location can help reduce transportation costs and improve logistical efficiency. Also, assess the accessibility and transportation inf […]

31

2023

Water chiller, you deserve it!

Water chiller is a refrigeration device that provides constant temperature, constant flow, and constant pressure cooling water. It absorbs indoor heat by circulating the refrigerant in the refrigeration system and releases the heat outdoors through the coolant. The working principle of a chiller is based on a refrigeration cycle, usually consisting of four main components, including a compressor, condenser, expansion valve, and evaporator. The following is a brief description of the working principle of the chiller: Compressor: The compressor is the core component of a chiller, responsible for compressing the refrigerant into high-temperature and high-pressure gas, and delivering it to the condenser. Condenser: The condenser is the second component of the refrigeration cycle, which converts high-temperature and high-pressure refrigerant into high-pressure liquid through cooling. The cooling method is usually achieved by dissipating heat […]

19

2023

How to Improve Cold Storage Efficiency? Pay Attention to Maintenance and Cleaning

Cold storage is a device used for storing and preserving food, typically used in commercial and industrial settings. In order to ensure the normal operation and maintain hygiene of the cold storage, regular maintenance and cleaning are necessary. Next, the editor will introduce the maintenance and cleaning methods of cold storage, as well as the precautions during use. 1、 Maintenance methods for cold storage 1. Regularly clean the air filter. The air filter is an important component inside the cold storage, which can prevent dust and bacteria from entering the interior of the cold storage. Therefore, it is necessary to regularly clean and replace the air filter. 2. Check the sealing performance of the cold storage door. The cold storage door must be tightly closed to maintain the temperature inside the cold storage. If the door is poorly sealed, it will lead to an increase in temperature and affect the preservation effect of food. There […]

12

2023

Hot selling cold storage! Do you want to know more?

Cold storage is a kind of refrigeration equipment, which refers to the use of artificial means to create an environment different from the outdoor temperature or humidity. It is also a constant temperature and humidity storage equipment for food, liquid, chemical, pharmaceutical, vaccine, scientific experiments and other items. Cold storage is usually located near the shipping port or the place of origin. The cold storage is mainly composed of several parts: the storage body, the refrigeration system, the cooling system, the control system and the auxiliary system. Compared with refrigerators, the cooling area is larger and has a common cooling principle. Cold storage can be divided into fresh storage, refrigeration storage, and quick-freezing storage according to the use. The temperature of the fresh-keeping storage is +3~+5°C, which is often used to keep vegetables and fruits fresh. The temperature of refrigeration storage is -20~-18° […]

6

2023

How Much Do You Know About Water Chiller?

Water chiller is a refrigeration device that provides constant temperature, constant flow, and constant pressure cooling water. It absorbs indoor heat by circulating the refrigerant in the refrigeration system and releases the heat outdoors through the coolant. Water chiller is different from general water cooling equipment in that it has a completely independent refrigeration system that is never affected by gas temperature or the environment. The water temperature can be adjusted and controlled, thus achieving high-precision and high-efficiency temperature control. The water chiller is equipped with an independent water circulation system, and the water inside the chiller can be recycled to save a lot of water. The working principle of water chiller is based on a refrigeration cycle, usually consisting of four main components, including a compressor, condenser, expansion valve, and evaporator. The following is a brief description of t […]

25

2023

Summer is here, do you want to build a summer resort?

Summer is approaching, today I will recommend a summer resort – Ice and Snow Park. In the ice and snow park, there are ski resorts, ice rinks, curling rinks, ice sculpture exhibition areas, snow falling areas, parent-child interaction areas, etc. Here, you can not only avoid the high heat, but also experience the fun of ice and snow. Focusun provides a complete set of indoor snow park construction services. In addition to the park construction, we can also provide services such as project background analysis, financial calculation, risk control and prevention. Next, I will give you a specific introduction to the construction of the project: Firstly, the project site selection is based on the principles of ecological and environmental protection, strong operability, venue safety, and there are many consumers in both the Eastern and Summer seasons; The site selection conditions are an area of 4000 square meters or more, with few ind […]

19

2023

A New Favorite in the Ice Machine Industry – Slurry Ice Machine

The emergence of ice machines has brought many conveniences to life, but the variety of ice machines is limited and cannot meet the needs of all customers. Focusun, a leading ice maker brand with nearly a century of glorious history, continuously innovates and brings European products and lifestyles that are simple, environmentally friendly, and full of design to the Chinese market. This time, Focusun set off again with his newly developed product, the slurry Ice Machine, with a firm attitude towards the established goals. How much do you know about slurry ice? Slurry ice is an aqueous solution containing suspended ice crystal particles. Research has shown that the cooling energy of slurry ice is 4-8 times higher than that of cold seawater, and its cooling capacity is 1.8-4.3 times that of cooling water. When cooling aquatic products, slurry ice has a higher cooling rate compared to traditional flake ice, which means cooling fish of the […]

12

2023

Ice machine science popularization: precautions and cleaning methods

Location: The ice maker should be placed in a well ventilated and temperature appropriate location, not in direct sunlight or near heat sources. Check the power supply: Check whether the power cord of the ice maker is grounded, whether the plug is secure, whether the wire is aging, and whether the power switch is normal. Operation method: Follow the instructions of the ice maker manual, do not overload, do not adjust the cooling temperature and ice making time arbitrarily, otherwise it will affect the lifespan and ice making effect of the machine. Attention to safety: The ice maker may generate high temperatures and pressures during operation. Do not open the machine or damage the sealing structure of the machine to avoid danger. Storage method: When not using the ice maker for a long time, the water tank should be emptied, the power cord should be unplugged, and a dry and ventilated environment should be maintained to avoid being affec […]

3

2023

The most comprehensive cold storage installation guide!

1、 Installation requirements for assembled cold storage 1. Collect materials from the accessory warehouse according to the engineering design and construction material list, and carefully check the materials and accessory models. 2. Before installing the cold storage, check the quantity of cold storage boards according to the shipping list. When loading and unloading the warehouse board, handle it with care, and lay anti-scratch layers on each layer of the warehouse board and the ground joints. 3. When assembling the cold storage as a whole, there should be gaps between the cold storage and the wall and roof. The ground or bottom plate must be horizontal, and the construction environment should be clean. 4. Before fixing the interior of the library with angle aluminum, it should be sealed with glass glue, and then fixed with angle aluminum by solid pulling and mortising. The spacing between pull rivets is 300 mm. The distance between th […]

27

2023

Amazing: The high-temperature snowmaking system reported by Xinhua News Agency

Focusun has always focused on how to produce snow that is close to natural snow, safe, non-toxic, low power consumption, and resistant to sliding and weathering. Through continuous efforts, high-temperature snow making system has been developed. Focusun’s high-temperature snow making equipment is not afraid of ambient temperature, air humidity, and inlet water temperature, breaking through the limitations of various environmental factors, and can make snow at a maximum temperature of 35 ℃. The snow produced is also easy to maintain its quality over a long period of time, and is resistant to sliding and weathering, making it more suitable for resisting sublimation and the impact of heat from light sources than natural snow. The high-temperature snow making system uses a ice flake crushing snow maker, using ice flakes as raw materials to make snow. The produced sheet ice is crushed into powder through an ice crushing device, and powdery i […]

27

2023

How to Choose a Satisfactory Ice Machine?

Many people want to buy ice machines, but they don’t know how to choose. Today, I will show you how to choose a satisfactory ice maker. When purchasing an ice machine, the following aspects should be considered: 1. Type of ice: different types of ice machines produce different shapes of ice, so ice makers should be selected according to the use of ice. For example, flake ice has no sharp edges and corners, and will not damage the external surface of the frozen object, so it is mainly used in seafood, aquatic products, food processing, etc. 2. Capacity: according to the amount of ice required, select the appropriate size of ice machine specifications to prevent the production of ice cubes from being insufficient or causing unnecessary waste. 3. Energy efficiency: When selecting an ice maker, be sure to ask clearly about the energy efficiency of the ice maker. An ice maker with high energy efficiency will greatly reduce energy costs […]

8

2023

Welfare of Supermarkets–Cube Ice Machine

There are many kinds of ice machines, and the most common one in daily life is cube ice machine. The cube ice machine is safe, efficient, energy-saving, durable and environmentally friendly. It is suitable for convenience store, cafe, milk tea shop, bar, banquet hall, fast food restaurants, and hotels. The shape of cube ice is square, and the size can be selected according to the needs. In addition to the cube ice machine, there are also options for snowflake ice machine, bullet ice machine and moon ice machine. Features of cube ice machine: 1. Adopt hot fluorine to doff ice, so the speed is fast. The whole ice-doffing process only takes 150-180 seconds; 2. Add the deicing drainage function, and drain the remaining water in the cold water tank instantaneously during deicing to make the ice cleaner and transparent; 3. The compressor imported from Europe and America has good performance, low noise and high reliability; 4. The machine head […]

2

2023

Ice Crusher: Make Ice Machine More Popular

Today, we will introduce the ice crusher, which can turn ice into small ice particles to meet people’s needs. For example, you bought an ice breaker, but you want to use it to freeze and keep fresh food. However, large block ice can not be well contacted with seafood in a large area, which requires ice crushing. After being processed by the ice crusher, large pieces of ice can become fragmented ice. Working principle: The power supply drives the motor to run, and the rotating motor drives the blade to start rotating at high speed, thus turning the large block ice into clastic ice. Features of ice breaker: 1.High quality ice crusher meets different ice crushing requirements. 2.The ice cubes after secondary ice crushing are more widely used. 3.Modular design makes operation safer and faster. 4.Made by SUS304, the ice crushing process is sanitary and safe. Model selection: There are two common ice crusher, one is tube ice crusher, a […]

31

2023

Efficient and Energy Saving Direct Cooling Block Ice Machine

In response to the national call for energy conservation and emission reduction, fully implement the new development concept, and highlight the corporate responsibility in promoting carbon peak and carbon neutralization, the ultra-low energy consumption ice maker came into being. Let’s learn about this direct cooling ice machine. Block ice is used for food processing, fishery production, cooling and preservation, factory cooling, etc. Block ice is divided into transparent ice and milky white ice, and transparent ice is mostly used for ice sculptures. Block ice plays an irreplaceable role in tropical areas. Under the same environmental conditions, block ice is not easy to melt and its storage life is relatively long; Large blocks of ice are very convenient in storage, handling and transportation, which is very important for small-scale fishing grounds and relatively remote areas. As a new type of ice machine, the direct cooling blo […]

29

2023

Comparison between Water-cooling Condenser and Evaporative Condenser

In the design and manufacture of the ice machine, we will select the appropriate condenser according to the different use environment. For example, in cold areas in winter, we recommend using air-cooled or evaporative condensers to prevent frost cracking. Let’s learn about the difference between water-cooled condenser and evaporative condenser. Water-cooled condenser For the open cooling circulating water system, because the cooling water absorbs heat and contacts with the air, CO2 escapes into the air, and dissolved oxygen and turbidity in the water increase, causing four major problems in the cooling circulating water system: corrosion, scaling, bacteria and algae growth and sludge. Therefore, in areas with good water quality and low ambient temperature, we often use water cooling. Through the cooling tower, the temperature of the system will be reduced after water circulation, so as to realize the normal operation of the ice ma […]

28

2023

Container Block Ice Machine: can be transferred

With the development of the refrigeration industry, when people choose refrigeration equipment, they not only consider the output, but also see whether the equipment is convenient to move – for example, there is no need to install the ice machine on site, or the work place is convenient to transfer. The emergence of container ice machine meets the needs of some customers. It does not need to be installed by yourself, which omits tedious installation steps, and the equipment is very convenient to move. Both brine cooling and direct cooling systems can be designed as container-type and installed in 20-foot and 40-foot containers that meet the international maritime transport standards. Users can choose the equipment according to their needs and site conditions. The specially made container is reinforced to prevent possible damage to the machine caused by the external environment, and can prevent sand, dust, rain and snow. Features o […]

11

2023

A New Type Snow Machine: Can Fall Snow Like Natural Snow!

In recent years, snow falling machines have increasingly appeared in some ice and snow parks, and have been popular with tourists. Why is snow falling machine so popular? What is the difference between it and the ordinary snow machine? Firstly, the snow falling machine adopts excellent snowflake clutch technology to form artificial snow. Artificial snow feels cold and looks like natural snow. It can achieve the falling effect of natural snowflakes. Secondly, the snow falling machine adopts Freon compression direct cooling technology, which can make snow quickly and evenly without storing snow in advance. Comparing with other snow machine, snow falling machine is small, which can be easily suspended on the wall or roof. It can be integrated with the scene. In addition, the falling snow machine will not be limited by the ambient temperature, inlet water temperature and air humidity. It can make snow stably in the four seasons. Lastly, th […]

21

2020

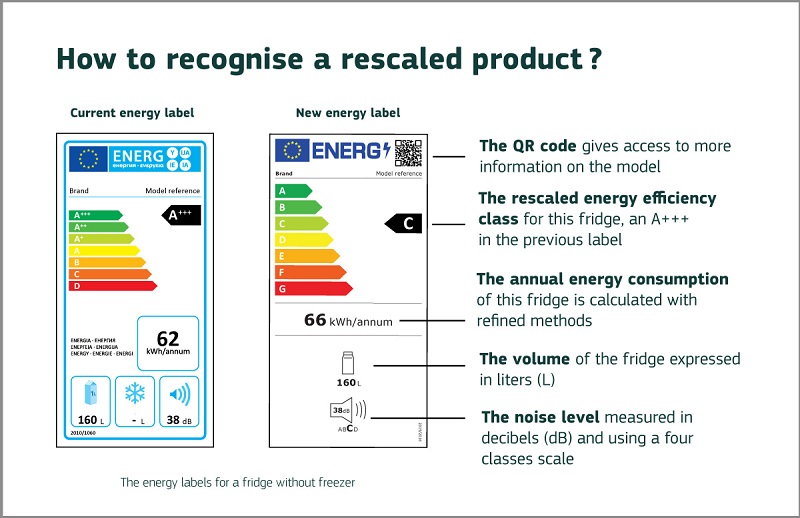

A new generation of EU energy labels

By using less energy to perform the same task, we can make significant energy savings and reduce waste. This is the basic principle of energy efficiency, and it is one of the most essential ways for the EU to move away from fossil fuels and achieve carbon neutrality by 2050. Improving energy efficiency will benefit society by reducing emissions and our dependency on energy imports, while also lowering energy costs for citizens and businesses across the EU. The EU energy label The EU energy label is – together with minimum “ecodesign” requirements – a success story that has been key in boosting the energy efficiency of everyday electric appliances like lighting, heating, fridges, freezers and televisions, but also products like fuel boilers, tyres and air conditioners. Since its inception in 1994, EU energy labels have helped steer and guide consumers to choose products that use less energy and therefore, over the products life span, als […]

14

2020

Cooling as a Service encourages new models for sustainable cooling

Cooling as a Service, an initiative aimed at scaling up clean and efficient cooling, has unveiled the winner of its Cooling as a Service (CaaS) Prize, aimed at stimulating new models for sustainable cooling, in what is set to become a $1.5 trillion market over the next 10 years. “Inexpensive cooling systems are cheap to buy but come with a plethora of hidden financial and environmental costs: high energy use, frequent breakdowns, and the use of harmful synthetic refrigerants,” said Thomas Motmans, sustainable energy financespecialist of BASE (The Basel Agency for Sustainable Energy), a Swiss not-for-profit foundation and specialised partner of United Nations Environment which is pioneering the CaaS model. “The climate emergency requires us to rethink our approach to cooling from the bottom up, to tackle emissions, cut waste and improve livelihoods – all while keeping costs low for end users. Fortunately, the Cooling as a Service busines […]

11

2019

Artificial Snow 2-2

The Manufacturing Process The production of artificial snow requires a series of devices that can move water and air up the mountain, combine them with a nucleating material, and spray them into the air as small droplets. Typically, the system is installed during the summer months and operated at night after the slopes have closed. Installation of the system 1 Artificial snow making requires an entire system to be installed on the mountain slope. This system includes a series of water pipes, electric cables, pumps, and compressors in addition to the snow making machines. First, plans showing the layout of the system are drawn. Then the water pipes and cables are laid in long trenches traversing the entire slope. The trenches must be dug significantly deep so water does not freeze during the winter months. At various points along the water line, valves and hoses are installed to bring water to the surface. Hay bales are placed around the […]

2

2019

Artificial Snow 1-2

Artificial snow is small particles of ice that are used to increase the amount of snow available for winter sports such as skiing or snow boarding. It is produced by a machine that uses a high-pressure pump to spray a mist of water into the cold air. The water droplets subsequently crystallize to form fake snow. The first commercially successful machines were developed in the 1950s and improvements in technology have steadily been introduced. With the increase in the popularity of winter sports, the artificial snow market is expected to show significant growth. Background The machines that produce artificial snow are designed to mimic the way that natural snow is made. In nature, snowflakes are formed when the temperature falls below 32° F (0° C). Atmospheric water then condenses on particles in the air and crystallizes. This action produces snowflakes that have a variety of sizes and shapes. In a snow machine, water is first mixed with […]

25

2019

Focusun New System for Snowmaking