13

2026

Premier Ice Packaging Machines for Modern Ice Factories: Efficiency & Hygiene Compared

In the ice-making and distribution industry, the packaging step often becomes a major bottleneck. The manual bagging process is slow and it also brings hygiene risks.So, for any ice factory, a reliable ice packaging machine is necessary. This is where automated solutions from leaders like Focusun Refrigeration help. This article compares the main types of ice packers on the market and shows why Focusun’s turnkey ice packaging solutions are a top choice.

Why Automated Ice Packaging is a Game-Changer for Ice Factories

The old method of workers manually bagging ice is not efficient anymore. Modern ice factories and distribution centers need to deliver large volumes of ice that is perfectly weighed, securely sealed, and clean. Manual processes often get bag weights wrong, and that hurts profits. Also, they can create sanitation problems. This risks the food-grade safety of the ice, which is very important for ice supplied to drinks, fisheries, and healthcare.

An automated or semi-automated ice packing system ensures precise weighing, increases speed a lot, reduces human contact with the ice and creates a consistent product. So, for any operation that wants to grow, choosing the right ice bagging machine is a key decision. It decides profitability and growth.

Ice Packer Showdown: Semi-Automatic vs. Fully-Automatic Machines

Most ice factory owners choose between two levels of automation. Here is a comparison of semi-automatic ice packers and fully-automatic ice packaging machines.

| Aspect | Semi-Automatic Ice Packer | Fully-Automatic Ice Packer |

| Core Function | Handles feeding, weighing, and filling. But sealing is often a separate manual step. | Performs the complete cycle: feeding, weighing, filling, sealing, printing, and counting. Punching is an extra option. |

| Best For | Small to medium operations or businesses with lower daily output needs. | Large-scale ice factories, high-volume commercial ice plants. |

| Throughput Capacity | Moderate | High |

| Labor Involvement | Needs an operator to manage bags and start cycles. | Minimal. The system runs continuously. Workers only need to watch it and change bag rolls. |

| Initial Investment | Lower. It gives a cost-effective start to automated packaging. | Higher. But this is okay because it greatly cuts labor costs and gives much higher output for large needs. |

| Key Advantage | A good balance of automation and cost control. It is also simpler to run and fix. | Maximizes output and consistency. It makes a fully finished, professional bag ready for distribution. |

Why Focusun’s Ice Packaging Solutions Lead the Market

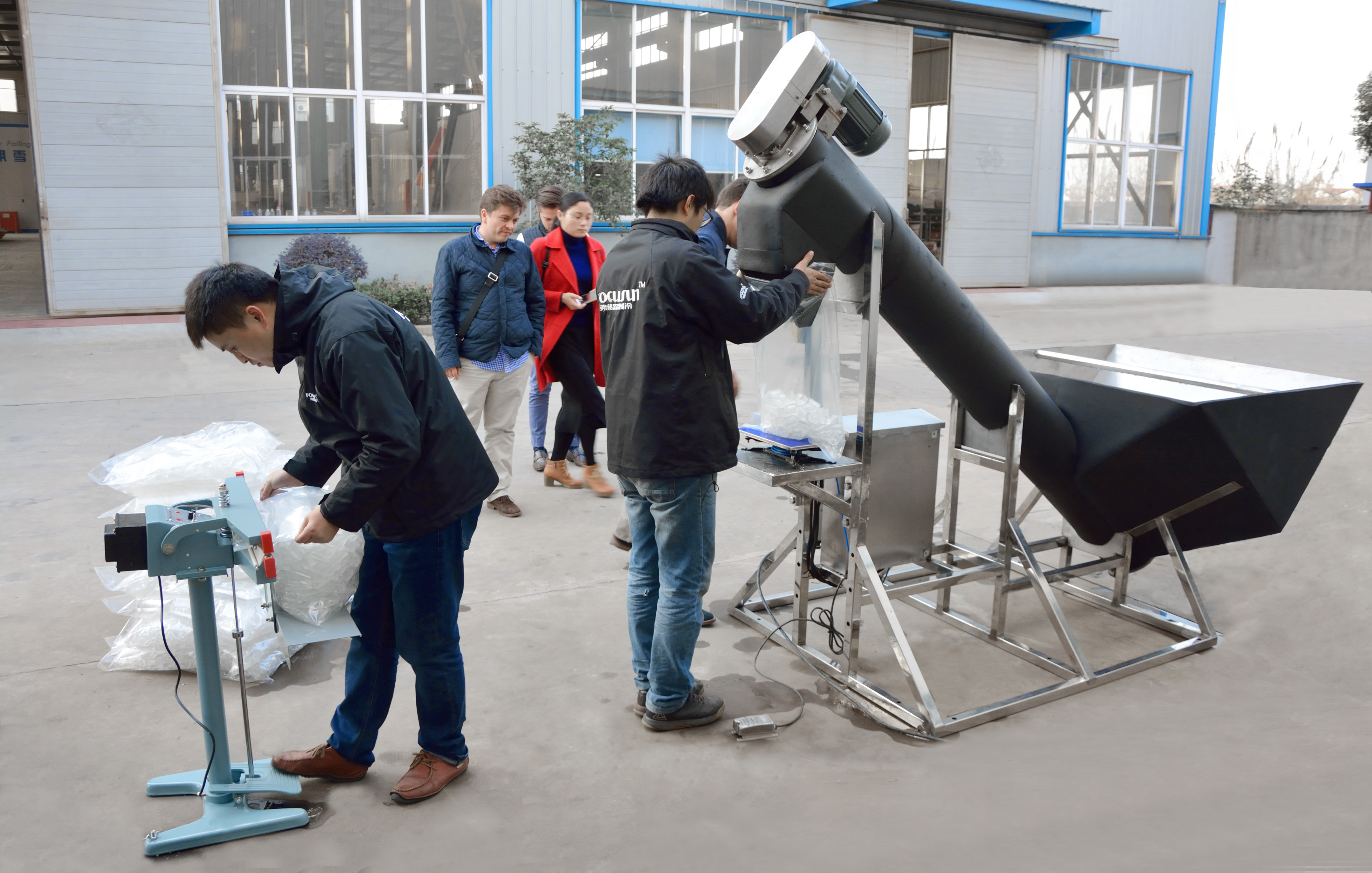

Focusun Refrigeration does not just sell machines; it provides customized ice factory solutions. With years of experience in industrial cooling, Focusun’s ice packaging equipment is made for real-world durability and performance. The brand’s focus is clear in two main areas:top-quality components and deep customization.

Built with Premium, Reliable Components

Whether you pick a semi-automatic or fully-automatic model, Focusun machines are built to last. Key parts come from top international brands:

Electrical & Control Systems:They use Schneider Electric panels, Siemens PLCs, and Omron sensors. This makes operation stable, safe, and smart.

Drive & Motion:They use Panasonic main motors and servo motors for precise movement.

Hygienic Design:All parts that touch the ice use high-quality SUS304 stainless steel. This meets food safety standards and is easy to clean. PVC or stainless steel conveyor belts keep bags clean.

Tailored to Your Specific Factory Workflow

Focusun knows that no two ice plants are the same. Their professional engineering team works with clients to customize the solution:

Capacity Matching:They have models from 500 kg/h to 3000 kg/h to fit your scale.

Bagging Flexibility:Bag weight can be set easily, usually from 1 kg to 12 kg or more. The machines can use different “pillow” bag types.

Conveyor & Layout Customization:Auger lengths and conveyors can be changed to fit your factory layout.

Function Options:You can add date printing or a handle punch to the automatic line.

This mix of strong hardware and flexible engineering means a Focusun ice packaging system is not just a machine—it is a long-term partner for productivity.

Effective Execution and Integration of Large, Complex Projects

Focusun can handle large projects well. We provide complete solutions from ice making to packaging. For example, we once delivered a full ice plant for an international client. This project included tube ice machines and an automatic packing system. We completed it in a very short time.

We connected multiple ice machines to a fully automatic packing line. We used a unified PLC control system. This achieved full automation from production to bagged ice. The system ensures continuous high output. It greatly reduces the need for workers and lowers operating costs. This project shows we can deliver reliable and efficient large-scale industrial solutions.

Frequently Asked Questions

Q1: How do I decide between a semi-automatic and a fully-automatic ice packer?

A1: It depends on your daily output and labor goals. If your volume is moderate and you want better accuracy and hygiene without a high cost, a semi-automatic ice packing machine is best. But if you run a large plant with high, continuous output and need to save labor and maximize speed, choose a fully-automatic ice packaging machine.

Q2: Are Focusun ice packers suitable for direct food-contact ice?

A2: Yes. A key Focusun advantage is strict hygiene. Using SUS304 stainless steel in all contact areas makes their machines perfect for packaging edible ice for drinks, food processing, and stores.

Q3: Can the machine handle different bag sizes and weights?

A3: Yes. A major feature of Focusun’s ice packaging solutions is adaptability. The weighing system can be adjusted across a wide range, and the bagging mechanisms can be set for different bag sizes. This gives you great flexibility.

Conclusion

Finally, choosing the right ice packaging machine is a key investment. It affects your profits, brand name, and daily operations.

Do not let slow packaging weaken your ice production.Contact the Focusun team today to talk about your capacity and factory space.

Contacts & Support

Focusun Refrigeration CorporationRoom 603, Baohong Center

No. 7755 Zhongchun Rd

Shanghai CHINA

ZipCode: 201100

Tel: +86-21-5108 9946

Fax: +86-21-5227 2259

Email: enquiry@focusun.com

Sales: sales@focusun.com

Marketing: marketing@focusun.com

Press: press@focusun.com

Newsletter: newsletter@focusun.com