22

2026

How Does the Focusun Vacuum Cooler Cooling Efficiently For Food Processing?

Here’s what happens in food processing facilities every single day. Fresh ingredients arrive carrying heat—field heat from crops picked hours earlier, processing heat from cutting and handling, residual warmth from manufacturing steps. That heat is the enemy. Every minute your product stays warm, quality degrades. Bacteria multiply. Enzymes keep working. Texture changes. Flavor compounds break down. Color fades.

Traditional cooling tries to solve this by blowing cold air or circulating chilled water around products. Which works eventually. Problem is, eventually isn’t fast enough for modern quality standards. Air cooling takes hours to pull heat out of dense products. Water cooling risks contamination and damages delicate surfaces. Food processors dealing with tight margins and demanding customers can’t afford slow, uneven cooling.

Vacuum cooling machine approaches the problem completely differently. Instead of trying to cool products externally with cold air or water, you change the physics entirely. Drop the pressure, change the boiling point of water, and suddenly the product cools itself from the inside out. Sounds strange until you understand how it actually works.

How Does the Focusun Vacuum Cooler Cooling Efficiently?

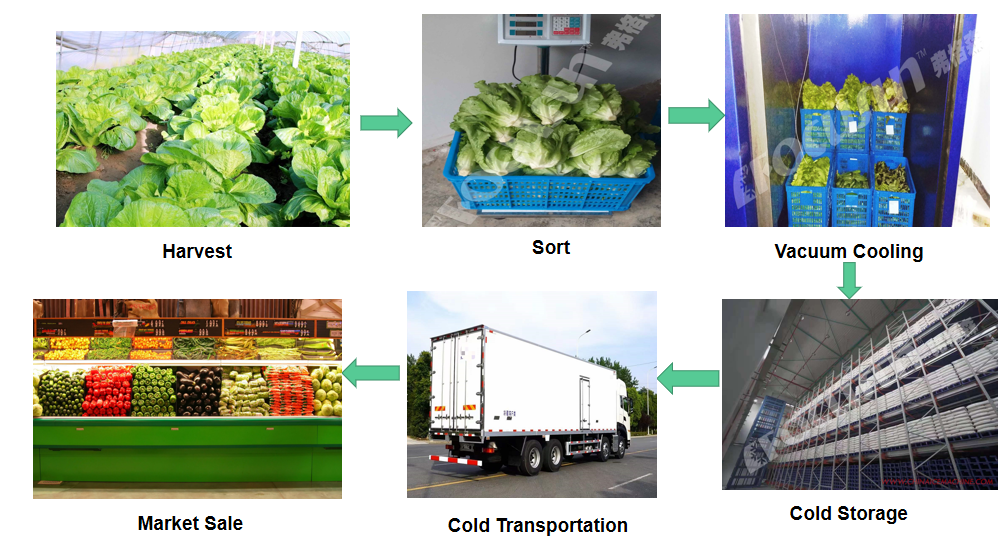

The workflow of a vacuum cooler is clear and efficient:

1.Place food, seafood, fruits, vegetables, or cooked products into the vacuum chamber and seal it.

2.Activate the vacuum pump to rapidly reduce the internal pressure to near-vacuum levels.

3.At this point, the boiling point of water on the surface and within the product tissues drops significantly, causing moisture to evaporate quickly.

4.The phase change of water from liquid to gas absorbs a large amount of latent heat of vaporization (approximately 2260 kJ/kg), which is directly drawn from the product itself. This lowers the core temperature uniformly and rapidly to the target low temperature (typically close to 0°C) within just 15 to 30 minutes.

5.The refrigeration system then activates to condense and discharge the water vapor, completing the cycle.

Core Advantages of Vacuum Cooling

Vacuum cooling system achieves fundamental improvements in efficiency and quality across multiple dimensions, delivering significant value to the food and seafood processing industry:

1. Ultra-Fast Cooling

Vacuum cooling can rapidly lower the core temperature of products to the target level within 15–30 minutes, achieving minute-level high-efficiency cooling. This rapid temperature reduction immediately inhibits respiration and enzyme activity, maximizing the retention of freshness and nutrients from the point of harvest or processing, and creating a valuable “time window” for subsequent cold chain logistics.

2. Uniform Cooling: Damage-Free Preservation

Vacuum cooling is an evaporative heat absorption method that works from the inside out. Surface and core cool together. Temperature remains uniform throughout the cooling process. Its causes no mechanical damage to product surfaces, effectively preventing chilling injury and condensation. Some models are equipped with a water-spraying pre-cooling system. They precisely compensate for moisture loss during rapid cooling, perfectly addressing the preservation challenges of dehydration-prone products like leafy vegetables.

3. Enhanced Hygiene and Safety

The sealed vacuum environment provides hygiene advantages traditional open-air cooling can’t match. During conventional cooling, products remain exposed to ambient air carrying potential contaminants. Vacuum chambers isolate products completely during the critical cooling phase. No airborne contamination. The cooling process removes free moisture from the surface, inhibiting the growth of microorganisms. This makes it suitable not only for fruits, vegetables, and seafood but also fully compliant with high-standard food safety requirements for ready-to-eat foods, sauces, and other products.

4. Effective Freshness Locking

By rapidly lowering temperatures, vacuum cooling effectively inhibits product physiological activity and microbial growth, significantly extending shelf life. While preserving product color, texture, and nutritional content, it substantially reduces loss rates during processing, storage, and transportation, enhancing overall economic efficiency.

Vacuum Cooling vs Traditional Cooling

| Comparison Dimension | Vacuum Precooling | Traditional Cooling |

| 1. Cooling Speed & Time Efficiency | Ultra-fast, minutes | Slow, hours |

| 2. Cooling Uniformity & Quality | Uniform, non-damaging | Uneven, potentially damaging |

| 3. Operational Process & Hygiene | Simplified Process, High Hygiene | Complex Process, Contamination Risk |

| 4. Preservation Effect & Loss Control | Highly effective, minimal loss | Rapid quality degradation, high loss |

Common Questions About Focusun Vacuum Cooler

Q1.Is the vacuum cooler customizable?

Yes, the following options are available for customization:

(a)Door: A. Swing door; B. Sliding door; C. Electric door

(b)Condensation method: A. Air-cooled; B. Water-cooled; C. Evaporative cooling

(c)Refrigeration system: A. Refrigerant system (R404a); B. Ammonia system

(d)Vacuum tank material: A. Carbon steel; B. Stainless steel

(e)Additional configurations: A. Water precooling system; B. Trolley loading system.

Q2.How long can the equipment preserve vegetables and flowers?

Depending on the type of vegetables and flowers, vacuum cooling can generally preserve them for 30 to 50 days.

Q3.In which fields is this machine applicable?

Vacuum cooling machine are not only suitable for large-scale food processing plants but also widely applicable in Seafood Processing、Ready-to-Eat Foods & Central Kitchens、Prepared Foods & Seasoned Products、High-Value Produce & Flowers.

Conclusion: From “Preservation” to “Freshness Locking” with Focusun Vacuum Coolers

The vacuum cooler transforms the first step in post-processing for fresh food and seafood from traditional slow cooling into a rapid and proactive “quality solidification process.” In today’s market, where consumers are increasingly discerning about quality, vacuum cooling builds a solid competitive advantage—longer shelf life, better color retention, and superior texture—all critical factors for market success.

Choosing an experienced professional vacuum cooler manufacturer like Focusun ensures comprehensive support from core vacuum technology and uniformity control to system stability.

Contacts & Support

Focusun Refrigeration CorporationRoom 603, Baohong Center

No. 7755 Zhongchun Rd

Shanghai CHINA

ZipCode: 201100

Tel: +86-21-5108 9946

Fax: +86-21-5227 2259

Email: enquiry@focusun.com

Sales: sales@focusun.com

Marketing: marketing@focusun.com

Press: press@focusun.com

Newsletter: newsletter@focusun.com