8

2026

What Is A Vacuum Cooler For Fresh Food And Why Does It Improve Cooling Efficiency?

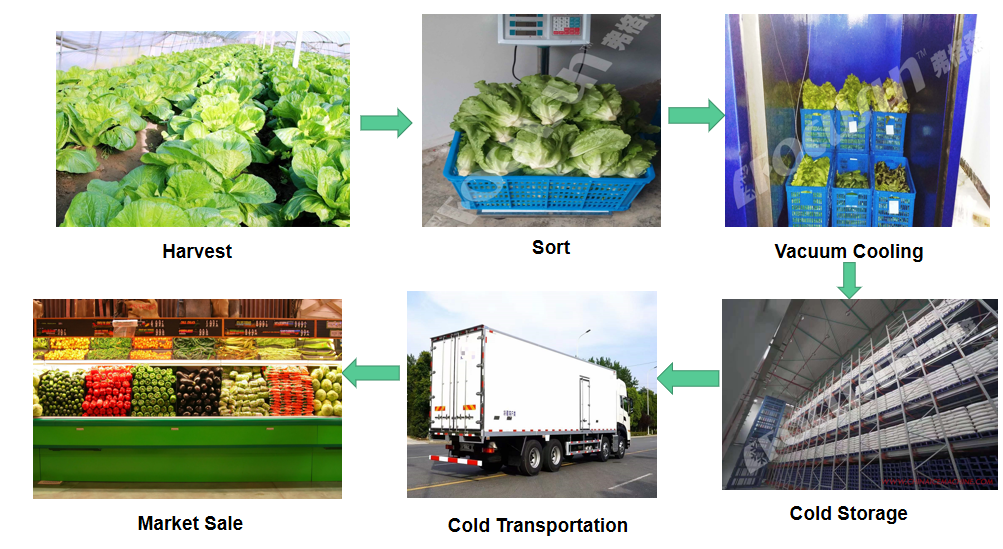

In the fresh food supply chain, from the field to the consumer’s table, quickly and evenly removing the “field heat” carried by fruits, vegetables, and flowers after harvesting is the first critical hurdle determining their freshness, taste, and shelf life. Traditional methods like air cooling and water cooling are slow, have large temperature differences between the inside and outside, and are prone to causing surface damage or cross-contamination, making them unsuitable for the stringent efficiency and quality control requirements of modern high-quality supply chains. Vacuum cooling technology has emerged to address this core challenge, redefining the efficiency and quality standards of post-harvest processing of fresh agricultural products with its unique physical principles.

What Is A Vacuum Cooler?

A vacuum cooler is a highly efficient cooling system that utilizes the principle of heat absorption through water evaporation in a vacuum environment to achieve rapid and uniform cooling of items. It doesn’t “cool” objects with cold air, but rather creates a low-pressure environment that causes the internal moisture to boil and evaporate at low temperatures, instantly removing a large amount of heat. Here’s what you’ll find inside one of these machines: First, there’s the vacuum chamber itself. That’s where your products sit during the cooling process. Then you’ve got the vacuum pump assembly, which is basically the heart of the operation. Its job? Suck out all the air and keep that low-pressure environment stable. And finally, there’s a refrigeration system that handles all the water vapor that gets created during the process. Without that, you’d just have steam everywhere.

How Does A Vacuum Cooler Work?

Let’s walk through what happens when you use vacuum cooling machine. You start by loading up your freshly harvested vegetables, flowers, or even cooked dishes into the chamber. Seal it up tight. Hit the switch, and the vacuum pump kicks in fast. Really fast. Within minutes, the pressure inside drops way down—we’re talking near-vacuum levels here. Now here’s where it gets interesting. Water normally boils at 100°C, right? But when you drop the pressure like this, water starts boiling at much lower temperatures. The moisture sitting on the surface of your lettuce or strawberries? It starts evaporating immediately. Even the water inside the cells begins to evaporate. This phase change—from liquid to gas—requires massive amounts of energy. And where does that energy come from? Directly from your product.

That’s the beauty of it. The food itself provides the heat needed for evaporation, which means its temperature drops uniformly throughout. We’re not talking about a slow cool-down over hours. This happens in 15 to 30 minutes, tops. Your product reaches near-freezing temperatures (close to 0°C) in less time than it takes to watch a sitcom. Meanwhile, the refrigeration system is working overtime, condensing all that water vapor and getting it out of the chamber. Circle complete.

Vacuum Cooling vs. Traditional Cooling: How Does It Significantly Improve Cooling Efficiency and Preservation of Fresh Food?

Compared to traditional cooling methods, vacuum cooling offers a fundamental and multi-dimensional efficiency improvement, directly addressing core industry pain points.

1. Time Efficiency: A Leap from “Hours” to “Minutes”

Traditional cold storage may require several hours or even tens of hours to bring the core temperature of a product to the required level, while vacuum cooler takes only 15-30 minutes. This rapid cooling immediately inhibits respiration and enzyme activity, maximizing the preservation of freshness and nutrients at harvest, creating a valuable “time window” for subsequent cold chain logistics, and significantly reducing quality degradation during the cooling process.

2. Quality Efficiency: Achieving Uniform Cooling and “Damage-Free Preservation”

Traditional methods often result in products being “cold on the outside and hot on the inside,” with temperature difference stress damaging cell structure. Vacuum cooling machine provides uniform cooling from the inside out, ensuring the surface and core temperatures are consistent, avoiding chilling injury and condensation. Its “evaporative heat absorption” physical process is gentle and will not cause mechanical damage to the product surface. Some models employ a water-spraying (water-added pre-cooling) design, which can accurately compensate for a small amount of moisture while rapidly cooling, perfectly solving the preservation problem of leafy vegetables and other easily dehydrated products, minimizing losses.

3. Operation and Hygiene Efficiency: Simplified Process, Enhanced Safety

Vacuum cooling is not limited by packaging, and cooling in boxes reduces secondary processing. Its sealed vacuum environment isolates external contaminants, and the cooling process itself removes some surface free moisture, which is unfavorable for microbial growth. This makes it suitable not only for fruits, vegetables, and flowers, but also for the rapid cooling of ready-to-eat cooked foods, sauces, and other products, meeting high-standard food safety production requirements such as HACCP.

| Comparison Dimension | Vacuum Precooling | Traditional Cooling |

| 1. Cooling Speed & Time Efficiency | Ultra-Rapid Cooling | Slow Cooling |

| 2. Cooling Uniformity & Product Quality | Uniform & Non-Damaging | Uneven & Potentially Damaging |

| 3. Operational Process & Hygiene/Safety | Simplified Process, High Hygiene | Complex Process, Contamination Risk |

| 4. Preservation Effect & Loss Control | Highly Effective Freshness Lock, Minimal Loss | Rapid Quality Degradation, Higher Loss |

Applications of Vacuum Cooling Machines

This high-quality vacuum cooling system isn’t just for industrial operations, though they certainly use it. Small-scale farmers growing premium lettuces? They need this. Restaurants preparing large batches of cooked food that must be chilled quickly for food safety reasons? Absolutely. Flower growers shipping delicate blooms overseas? Can’t do without it.

Common Questions

Q1.Can vacuum coolers be used for cooling cooked foods?

Absolutely. Vacuum cooling machine is entirely made of R304 stainless steel, and its operation produces no pollutants, so it can be directly installed on the food processing production line. It can be used for everything from baked and fried foods such as bread, cakes, and fried fish balls to meats and vegetables.

Q2.How long can the equipment preserve vegetables and flowers?

Depending on the type of vegetables and flowers, vacuum cooling can generally preserve them for 30 to 50 days.

Q3.Is the vacuum cooler customizable?

Yes, the following options are available for customization:

(a)Door: A. Swing door; B. Sliding door; C. Electric door

(b)Condensation method: A. Air-cooled; B. Water-cooled; C. Evaporative cooling

(c)Refrigeration system: A. Refrigerant system (R404a); B. Ammonia system

(d)Vacuum tank material: A. Carbon steel; B. Stainless steel

(e)Additional configurations: A. Water precooling system; B. Trolley loading system

Conclusion: Choose The Efficient And Safe Solution From “Preservation” to “Freshness Locking” – Focusun Vacuum Cooler

The vacuum cooler is far more than just a cooling device. It represents a precise and efficient “active freshness locking” concept based on physical principles. It transforms the first step in post-harvest processing of fresh produce from a slow, passive “cooling process” into a rapid, proactive “quality solidification process.”For anyone serious about building a brand around fresh, high-quality produce, this technology creates a competitive moat. Your competitors are still using conventional cooling? Their products are degrading while yours stays pristine. Your shelf life is longer. Your color is better. Your texture is superior. Those differences matter enormously in today’s market where consumers notice quality and remember it. The bottom line is simple: vacuum cooling represents a fundamental shift in how we think about freshness. Not as something that inevitably declines, but as something that can be captured and held. That’s powerful. That’s what separates premium products from ordinary ones. And in an industry where margins are tight and quality is everything, that edge might be exactly what you need.

Choosing solutions from experienced professional vacuum cooler manufacturer like Focusun ensures reliable supply chain assurance from core vacuum technology and uniformity control to system stability, truly transforming this efficient technology into a core driver for cost reduction, efficiency improvement, and value enhancement in the fresh produce industry.

Contacts & Support

Focusun Refrigeration CorporationRoom 603, Baohong Center

No. 7755 Zhongchun Rd

Shanghai CHINA

ZipCode: 201100

Tel: +86-21-5108 9946

Fax: +86-21-5227 2259

Email: enquiry@focusun.com

Sales: sales@focusun.com

Marketing: marketing@focusun.com

Press: press@focusun.com

Newsletter: newsletter@focusun.com