13

2025

Why More Industries Are Turning to Flake Ice Machines? The Hidden Power Behind Modern Temperature Control

In the evolving landscape of modern refrigeration and industrial cooling, flake ice machines are quietly becoming indispensable across diverse sectors — from seafood preservation and meat processing to concrete cooling and chemical production.

Far from being just an “ice maker,” the flake ice machine has emerged as a core temperature-control system that directly impacts product quality, operational efficiency, and energy performance.

This article explores why more industries are adopting flake ice systems, the technology behind them, and how they reflect the next phase of industrial refrigeration innovation.

Ice as a Production Element — Not Just a Cooling Medium

In industrial applications, ice has long surpassed its traditional role as a simple cooling agent.

Today, it is recognized as a critical production element that affects quality, safety, and productivity across various processes.

- Seafood & Food Processing: Flake ice quickly reduces product temperature, slows metabolic activity, and preserves freshness and color.

- Meat Processing: Ice mixed with raw materials helps maintain a low temperature during grinding or mixing, preserving elasticity and texture.

- Concrete Cooling: In hot environments, adding flake ice to concrete controls hydration temperature, preventing cracking and ensuring structural integrity.

- Chemical & Pharmaceutical Industries: Ice is used to stabilize reaction temperatures, ensuring process safety and consistency.

In short, ice has evolved from a by-product of cooling to a key input of production efficiency — and flake ice machines are the driving force behind this transformation.

Why Flake Ice Stands Out

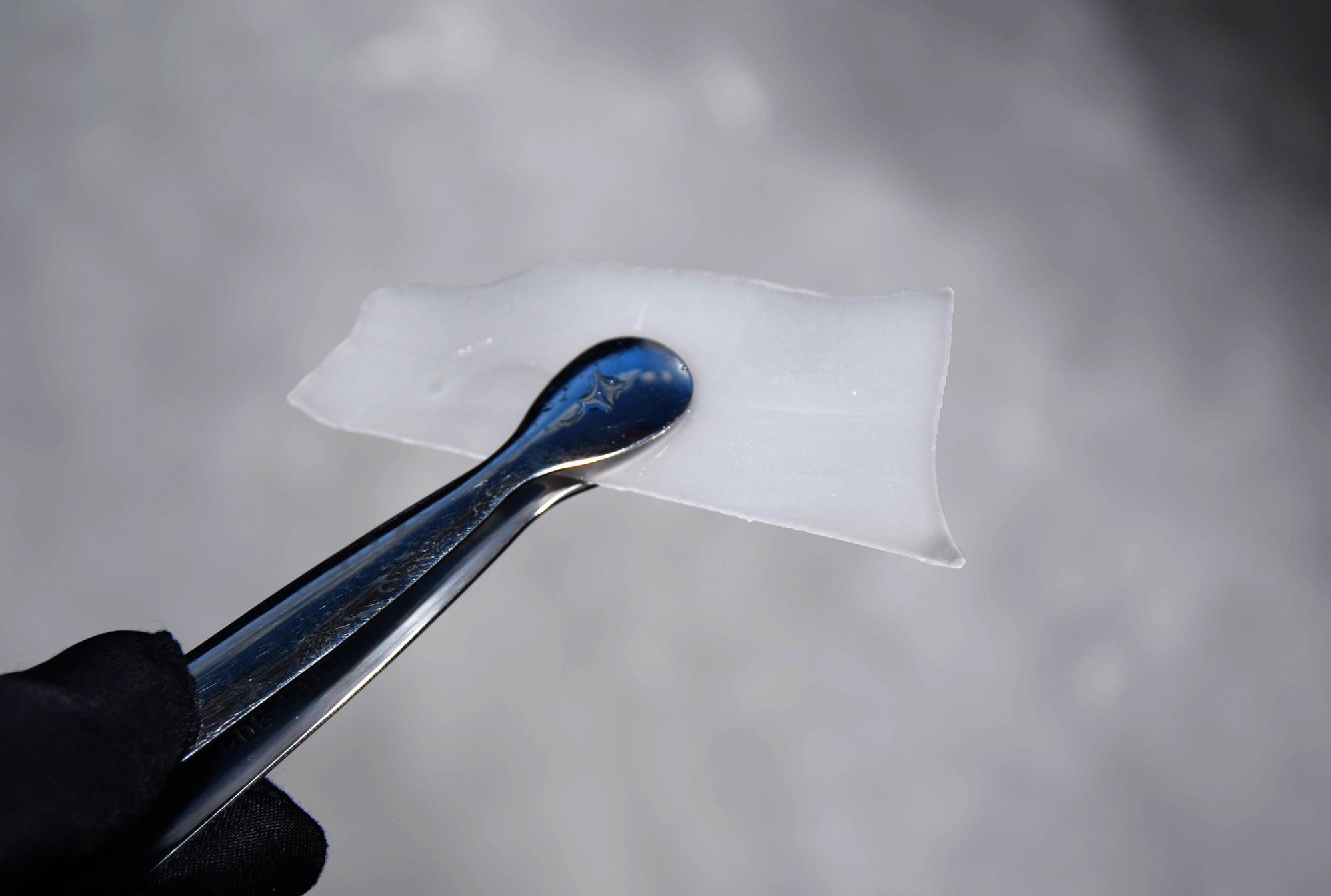

There are many types of ice: block ice, tube ice, cube ice, plate ice, and flake ice.

Among them, flake ice offers the most versatile and efficient cooling solution, thanks to its physical and operational advantages.

- High Heat Exchange Efficiency

Flake ice is thin (1.5–2.5 mm), providing a large contact surface that enables rapid heat transfer and faster cooling. - Excellent Surface Contact

Its irregular, soft flakes can fully adhere to any surface, ensuring uniform temperature distribution without localized hot spots. - Gentle and Non-Damaging

Unlike hard cube or tube ice, flake ice does not damage delicate food products — making it ideal for seafood and meat applications. - Easy Storage and Automation

Flake ice is loose, non-caking, and flows easily, allowing seamless integration with automatic ice delivery and dosing systems.

Flake ice achieves a unique balance between cooling efficiency and operational flexibility, perfectly suited for modern industrial processes.

Technological Progress: From Ice Maker to Intelligent Cooling System

Behind every high-performance flake ice machine lies a sophisticated combination of thermodynamics, materials engineering, and automation.

Recent advancements are redefining what “industrial ice making” means:

- High-Efficiency Evaporators

Focusun adopts dry-type evaporator designs with chromium-plated or special alloy materials, ensuring superior heat exchange, corrosion resistance, and extended lifespan. - Eco-Friendly Refrigerants

Modern Focusun systems use environmentally friendly refrigerants such as R404A, R507, R717 (Ammonia), and R744 (CO₂), meeting international energy and sustainability standards. - Intelligent PLC Control

Advanced control systems allow automatic operation, fault detection, and remote monitoring, optimizing performance while minimizing downtime. - Modular & Customizable Design

Focusun provides air-cooled, water-cooled, and seawater flake ice machines with scalable capacity and flexible installation — tailored to diverse industrial demands.

Through continuous innovation, flake ice machines are evolving from traditional refrigeration units to integrated smart cooling systems.

Industry Impact: Redefining the Cold Chain

As global demand for food safety, sustainability, and energy efficiency rises, flake ice machines have become a vital component in the modern cold chain ecosystem.

- Essential for Cold Chain Expansion

From fishing ports to processing plants, flake ice provides on-demand cooling, reducing product loss and maintaining freshness during transport. - Energy Efficiency & Environmental Benefits

Compared with conventional cooling methods, flake ice systems achieve rapid temperature reduction with lower energy consumption. - Distributed Cooling Trend

Enterprises increasingly prefer on-site, point-of-use ice production, with flake ice machines serving as local cooling hubs. - Globalization & Localization

Chinese manufacturers, led by Focusun, are achieving international competitiveness by combining reliable quality, cost efficiency, and advanced automation.

In essence, flake ice machines are no longer auxiliary devices — they are becoming strategic assets in temperature management and operational optimization.

The Future: From Ice Production to Smart Cooling

The next generation of flake ice machines will not only produce ice — they will think, optimize, and communicate.

With the integration of IoT, AI, and data analytics, future systems will feature:

- Smart ice production based on real-time demand;

- Energy consumption optimization and predictive maintenance;

- Digital dashboards for carbon footprint and system efficiency;

- Full connectivity with cold storage and logistics platforms.

This shift marks the evolution from “mechanical cooling” to intelligent, data-driven temperature management.

Contacts & Support

Focusun Refrigeration CorporationRoom 603, Baohong Center

No. 7755 Zhongchun Rd

Shanghai CHINA

ZipCode: 201100

Tel: +86-21-5108 9946

Fax: +86-21-5227 2259

Email: enquiry@focusun.com

Sales: sales@focusun.com

Marketing: marketing@focusun.com

Press: press@focusun.com

Newsletter: newsletter@focusun.com